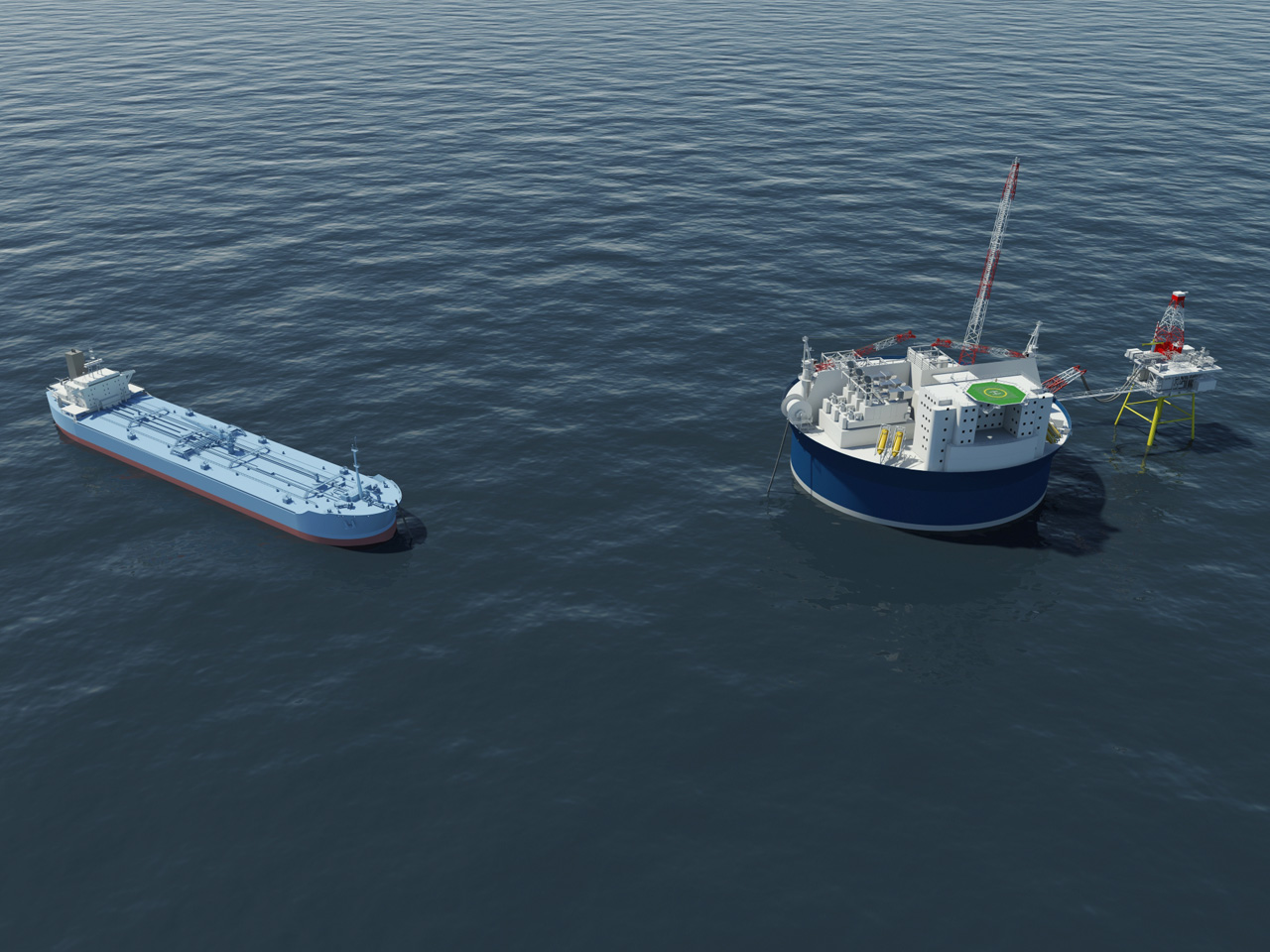

The Sevan design offers geostationary installation of a floater with storage capacity, low surge and heave and motions. These excellent motion characteristics enables installation sufficiently close for a retractable telescopic bridge to reach over to a fixed installation, typically a Wellhead Platform (WHP) or a Production Platform for vertical risers and dry trees.

This is a cost efficient alternative to more remotely installed storage capacities. Besides the well-known CAPEX and OPEX gains of a Sevan design through the elimination of the swivel and turret, the bridge linked solution adds more benefits from the walk-to-work over the retractable bridge. It significantly reduces the CAPEX and OPEX as one can have a common crew for both the storage floater and the WHP.

Hence, accommodation and associated utilities can be installed onto one location, and significant reductions in safety and life-saving systems follow on. Furthermore, cost benefits are also seen from elimination of subsea pipeline infrastructure connecting the fixed installation with the Sevan floater. The fixed platform is connected to the Sevan through flexible jumpers in a free-hanging arc configuration, without swivel and turret complexity and cost. Several studies have shown an availability for the bridge link to be satisfying for operation of this concept under harsh conditions of the North Sea, both purely for the purpose of storage, FSO, but also as an FPSO.

The available displacement and deck area of the Sevan floater allows equipment and systems to be relocated from the fixed platform onto the Sevan floater. It gives an opportunity to reduce the topside- and jacket weight of the fixed installation, typically having utilities such as power generation module on the Sevan unit. More equipment can be relocated, offering flexibility in between a traditional FSO and a FPSO. This allows space for drilling and well intervention equipment, hereunder allowing temporary drilling jackets operations. For High Pressure/ High Temperature (HP/HT) production facilities, or operations with heavy crude or wax challenges, this flexibility and the available footprint for utility systems are valuable, where such challenges can otherwise make the field development expensive and uneconomic.

The Bridge Linked Sevan Floater will have the same applications as for other Sevan FPSOs/FSOs with the accommodation and associated utilities, storage capacity and direct offloading to shuttle tankers. For certain services additional risers or umbilicals can be easily tied in without any swivel and turret restrictions. The bridge will be of a standard commercially available telescopic type, seen in use for other walk-to-work facilities. The distance to the fixed installation can be extended by installing a cantilevered and retractable landing area on the fixed platform side.

The Sevan Bridge Linked FSO/FPSO offers a cost efficient alternative where a fixed installation requires storage and/or production facilities with direct access between the installations.

Source: Sevan SSP