On June 2nd, 2017, “MTG-Dolphin” Shipyard delivered to Navigation Maritime Bulgare (Navibulgar) JSC the tug Alcor, the first of three vessels in series built to the RAmparts 2700 design by Robert Allan Ltd. This tug adds to the fleet of 4 tugboats in the Company and is the first tugboat built by the Bulgarian Shipyard MTG Dolphin PLC-Varna for Navibulgar (Bulgarian ship owner with more than 30 bulk carriers). The naming ceremony took place on June 2nd at Port of Varna and was attended by the Deputy Governor of Varna.

The vessel is named after the star Alcor from the Big Dipper constellation. Just as the star Alcor compliments the bigger star Mizar in this double star formation, the tug Alcor will be accompanying large vessels in the ports of Varna and Burgas.

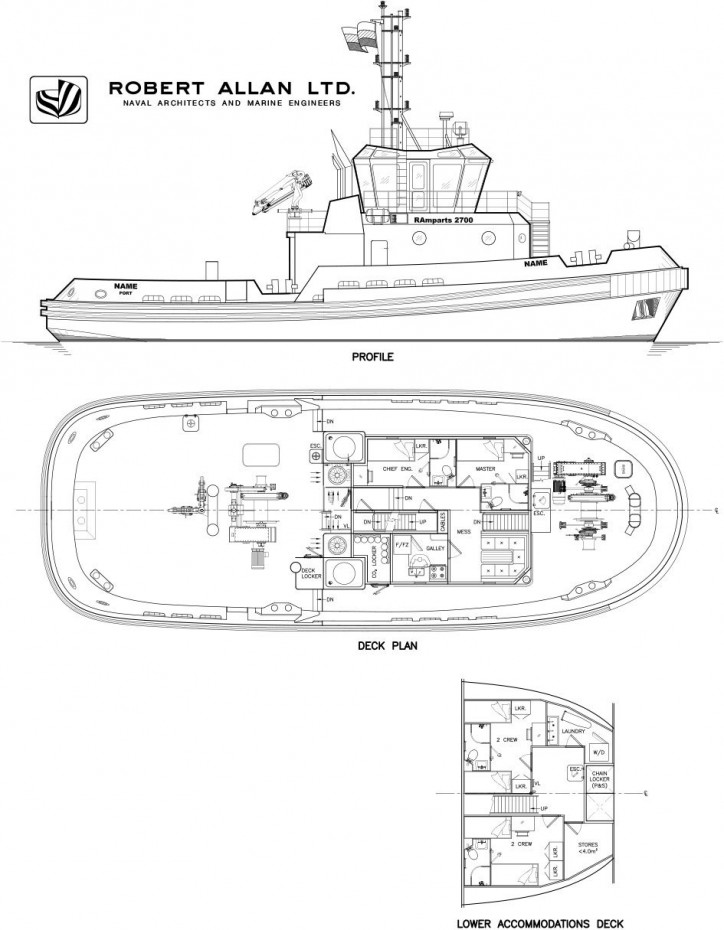

Alcor is a multi-purpose RAmparts 2700 tug working off a forward towing winch for ship handling and is equipped for coastal towing with towing gear aft including a tow hook and fittings for an optional winch.

Particulars of Alcor are:

- Length Overall: 27.60 m

- Beam, moulded, extreme: 10.00 m

- Depth, moulded (hull): 4.17 m

- Maximum draft: 3.95 m

- Gross Tonnage: 307

The tug was designed and constructed to satisfy all applicable Rules and Regulations of Bureau Veritas and Bulgarian Flag State.

The tank capacities are as follows:

- Fuel Oil: 57.8 m³

- Potable Water: 11.9 m³

- Main Engine Lube Oil: 1.0 m³

- Sludge Tank: 2.4 m³

- Grey Water: 4.5 m³

- Emergency Black Water: 4.5 m³

Trials results were as follows (average/maximum):

- Bollard Pull, ahead: 40/41 tonnes

- Bollard Pull, astern: 38/40 tonnes

- Free running speed, ahead: 13.1 knots

The vessel has been outfitted to the highest standards for a normal operating crew of six. The Master’s and Chief Engineer’s cabins are located on the main deck, with two additional double crew cabins located on the lower accommodation deck. A galley and mess room are also located on the main deck.

The deck machinery comprises a DMT Marine Equipment ATW-210 ship assist hawser winch on the bow, spooled with 150 m of 40 mm Dyneema line. The vessel is also fitted for an optional DMT Marine Equipment TW-010 towing winch aft with a capacity of 600 m of 40 mm steel wire. A DMT Marine Equipment DTH 45-90 tow hook is also fitted aft, on a towing staple. An AMCO VEBA V812FM knuckle boom deck crane is located on the aft deck.

The raised forecastle and elevated wheelhouse ensure good all-round visibility of the working decks. The reduced beam provides for a higher free running speed when transiting between ship assist tasks.

Main propulsion for each tug comprises a pair of CAT 3512C diesel engines, each rated 1,350 kW at 1600 rpm, and each driving a Veth VZ-1250A Z-drive unit, with a 2,000 mm diameter fixed pitch propeller.

The electrical plant consists of two (2) identical CAT C7.1 diesel gen-sets, each with a power output of 118 ekW, 50 Hz.

Source: Robert Allan Ltd.