A new briquetting technology developed by the Finnish company Evac for the first time in maritime waste handling, succeeded to reduce ships’ garbage volume by a factor of 10.

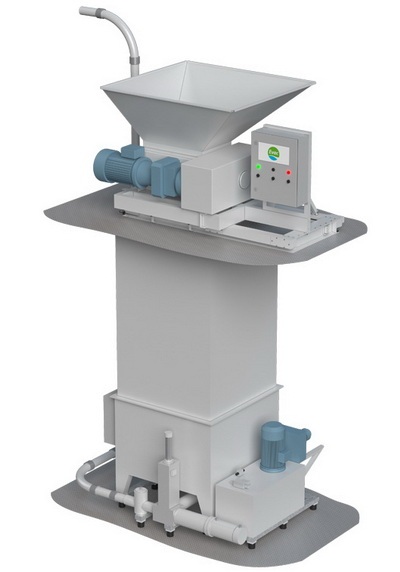

The Evac machine is paired with mixed waste macerator to form dry briquettes that can be stored for landing or incinerated at sea. Both machines cover an area of two square meters.

Considering the fact that there are legal restrictions on incineration of waste at sea, the new developed Evac’s technology, which provides 24/7 service, enables cruise ships to remain at sea over seven times more longer than before.

Evac’s Senior Process Specialist PhD, Jari Jokela, commented:

Evac’s Senior Process Specialist PhD, Jari Jokela, commented:

“In an environment when a ship may not use its incinerator, the garbage room will be filled floor to ceiling in two days. Evac’s briquetting technology enables a cruise ship to potentially operate without incineration or landing the waste for a full two-week voyage. Waste stored in the traditional plastic bags has density of 50 to 60 kilos per cubic meter, but the briquette’s density is 550 to 600 kilos per cubic meter”

According to Evac specialists, the new waste briquette technology leads to a significant reduction in operating costs, due to space savings. The waste processing was estimated to cost 25% less than incineration, when diesel and energy consumption was necessary to be used.

Some additional savings in total waste management costs can come into play when landing costs are factored in.

Some additional savings in total waste management costs can come into play when landing costs are factored in.

“Many European ports use ship gross tonnage as a basis of port fees. When transport costs of landed waste are calculated based on volume, ships using Evac’s briquetting technology also may enjoy major savings in landings costs in the future.”

Jokela says the idea for the technology came from witnessing how sawmills were creating briquettes. Then Evac created a similar technology, in a much more compact form, capable to be used at sea.

The Finnish company believes that their development can be applied on offshore oil platforms.

Usually onboard oil platforms work up to 1,000 workers, a reduced volume of garbage will mean less transportation costs for trips to the platform and back to remove waste.