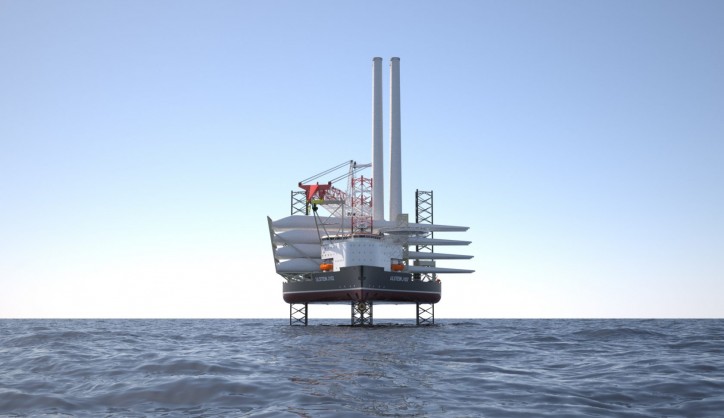

With the newly developed J102 heavy-lift jack-up design Ulstein presents its answer to the offshore wind industry’s need for fit-for-purpose, cost-efficient yet future proof wind turbine installation vessels. The new design is part of the X-JACK series of heavy lift jack-up designs.

“The launch of the X-JACK-series underlines Ulstein’s firm commitment to serve the offshore renewables industry”, says Tore Ulstein, COO Design & Solutions.

“Floating vessels we see as the preferred solution for foundation installation, where self-propelled jack-ups are the chosen tool for installing wind turbines”, continues Ko Stroo, product manager at Ulstein Design & Solutions BV. “With the ULSTEIN J102, the latest addition to our X-JACK series, we believe it is the closest one can get to an optimal yet cost effective jack-up design. Using a high capacity crane of up to 2,500 t and 160m hook height above deck, the J102 design will allow contractors to efficiently carry and install 4 x 15MW wind turbines per round trip.”

Key in the X-JACK design is its patented lay-out with a simple cruciform primary structure to achieve weight savings of 10 to 15% and create the most direct load path during preload operations. Positioning the legs widely apart in a square pattern results in efficient use of available deck space, at the same time effectively counteracting the crane overturning moments. This set-up also creates more body around the legs, enabling the use of large spud cans to reduce loads on the seabed. The combination of an innovative hull shape and vessel layout with well-proven technologies from reputable suppliers provides unrivalled heavy lift and cargo capabilities. It makes the ULSTEIN X-JACK the game-changing design that enables contractors to perform all wind turbine installations in the decades to come.

“The ULSTEIN X-JACK series is part of our strategy to complement our offshore wind design portfolio and strengthen our position as a long-term partner for supporting the offshore wind industry with sustainable and cost-efficient assets”, says Edwin van Leeuwen, managing director at Ulstein Design & Solutions BV. “Being innovative in our designs and focused on market needs, we achieved market leadership in offshore wind service vessels and heavy lift construction vessels. For wind turbine installation jack-ups, we like to become the industry’s preferred choice as well.”

The following key features characterize the ULSTEIN X-JACK series:

- Kite-shaped hull allowing for large leg spacings

- Main crane around stern leg on centreline

- Cruciform primary structural arrangement superior to torsion box solution

- No ballast water needed for lifting as the vessel is naturally balanced

- Large spud cans, reducing bearing pressures on seabed

- Vessel beam enables floating lift operations

- Increased propulsion efficiency as wake of spud cans does not interfere with thruster inflow

Main dimensions of ULSTEIN’s new J102 heavy-lift jack-up vessel design are:

- Length 145.0 m

- Width 88.4 m

- Depth 11.0 m

- Complement 120 POB

- Water depth 65 m

- Free deck area 6,500 m2

- VDL 10,500 t

- Wind turbine capacity 8 x 8 MW - 4 x 15 MW

- Main crane 2,500 t @ 39 m - 1,250 t @ 65 m

- Main hook height 160 m above deck

The X-JACK series includes the smaller J101, tailored for maintenance and exchange of wind turbines and the larger J103, designed to carry and install six next generation wind turbines to realize even the world’s most remote wind farm locations. The entire X-JACK series enjoys the key benefits of the patented lay-out.

ULSTEIN X-JACK series:

| J101 | J102 | J103 | |

| Length | 80 m | 145 m | 164 m |

| Width | 50 m | 88.4 m | 104 m |

| Deck area | 4600 m2 | 6500 m2 | 9000 m2 |

| VDL | 8500 t | 10500 t | 16000 t |

| 8 MW wind turbines | 2 | 8 | 12 |

| 15 MW wind turbines | 0 | 4 | 6 |

Source: Ulstein