Full transparency in real time as well as significantly increased efficiency for refrigerated transport chains – trade fair from February 6 to 8 in Berlin

Hamburg Süd will be presenting its future use of Remote Container Management (RCM) in Berlin during the upcoming Fruit Logistica, the world’s most important trade fair for fresh produce, including fruit and vegetables. In recent months, all the reefer containers used by Hamburg Süd have been outfitted with RCM technology.

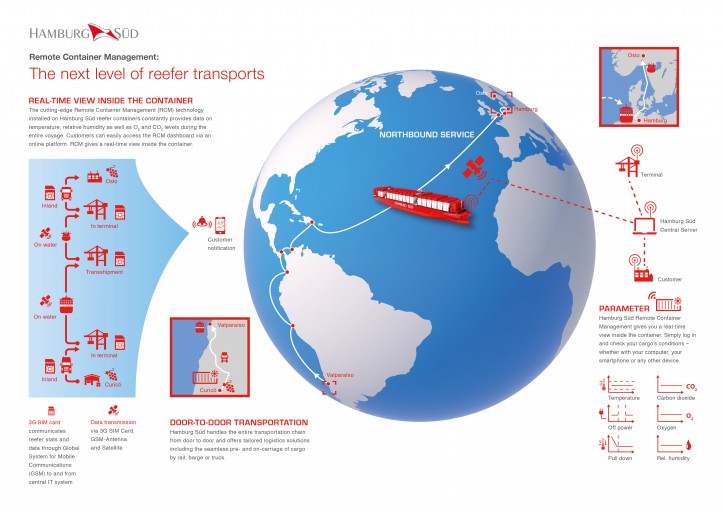

Using satellite and mobile radio technology, RCM makes it possible to monitor the refrigerated container and the condition of the cargo inside it – including its location, temperature profile, relative humidity, and concentrations of oxygen and CO2 – around the clock and in real time. In addition, certain settings can be adjusted remotely.

Unlike with the monitoring systems previously in place, customers can now use an online platform or an app on their tablet or smartphone to conveniently obtain an overview of the conditions of their cargo in the container at any time. In addition, they are automatically notified when individually defined parameters or limit values are reached.

“RCM will be a genuine game changer for the important reefer market,” says Frank Smet, Chief Commercial Officer (CCO) of Hamburg Süd. “The added value lies in the fact that customers can use this data not only to monitor their supply chain better, but also to make it significantly more efficient and secure.”

As part of the Maersk Group, Hamburg Süd can offer more than 370,000 reefer containers to its customers worldwide. This is the largest reefer fleet in the industry and, on top of that, every single one of them is outfitted with RCM, which ensures seamless availability of this innovative technology. This too, is unique in the industry. Testing is currently being conducted with customers, and RCM is scheduled to become available to all customers as from the third quarter of 2019.

Having complete control over the condition of the cargo enables customers to react to changes over the entire course of the transport rather than just at its destination.

“This offers shippers great potential for cost savings,” says Smet. At the same time, while the demands that customers place on carriers are increasing, carriers must be able to respond to these demands flexibly. “At Hamburg Süd, we make full use of the advantages offered by digitalization without neglecting personalized customer service and close consultation,” Smet adds. “With our experienced staff in over 250 offices worldwide, we can respond to the individual needs of our customers on the local level and at any time.”

Visitors to Fruit Logistica, which will be held in Berlin this year from February 6 to 8, can learn more about this and other issues related to the transport of temperature-sensitive goods at Hamburg Süd’s trade booth (Hall 25, Booth A–10)

Source: Hamburg Sud