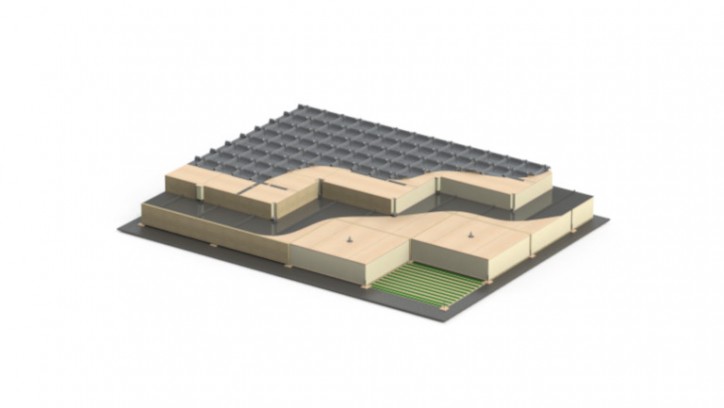

GTT has recently received an AiP from Bureau Veritas for the development of a new CCS evolution of the NO96 range. This CCS, named NO96 Flex, benefits from the NO96 proven technology as well as the use of an efficient foam panel insulation.

NO96 Flex maintains the main elements of the NO96 technology which have become key factors in its success. The insulating panels are mechanically anchored to the inner hull. The double metallic barrier concept remains with an unchanged secondary Invar® membrane but with an evolution of the primary membrane this is changed from Invar to corrugated stainless steel.

Initiated with NO96 L-03 technology, the integration of insulating foam panels within the NO96 system is now enhanced to take advantage of the continuous improvement in thermal performance of Polyurethane foam material.

The use of PU Foam at primary and secondary levels will allow GTT to propose a LNG Boil-off rate reduction down to 0.07%V per day(*1).

Since the beginning of this development in 2017, GTT has been in constant exchange with the major yards constructing NO96. The Mock-up phase is expected to begin in the first quarter of 2020.

Mr. Philippe Berterottière, Chairman and CEO of GTT declared: “With the development of NO96 Flex technology, GTT demonstrates again its philosophy for continuous improvement of its proven technologies.”

Mathieu de Tugny, COO, Bureau Veritas, Marine & Offshore commented: “Bureau Veritas is delighted to be able to accompany GTT and its ambitions to continue capturing and delivering innovating solutions in the field of LNG containment for the gas supply chain.”

(*1) - For standard 174,000 m3 LNG carrier

Source: GTT