Newbuilding Conversion FLNG design to deliver significant cost savings

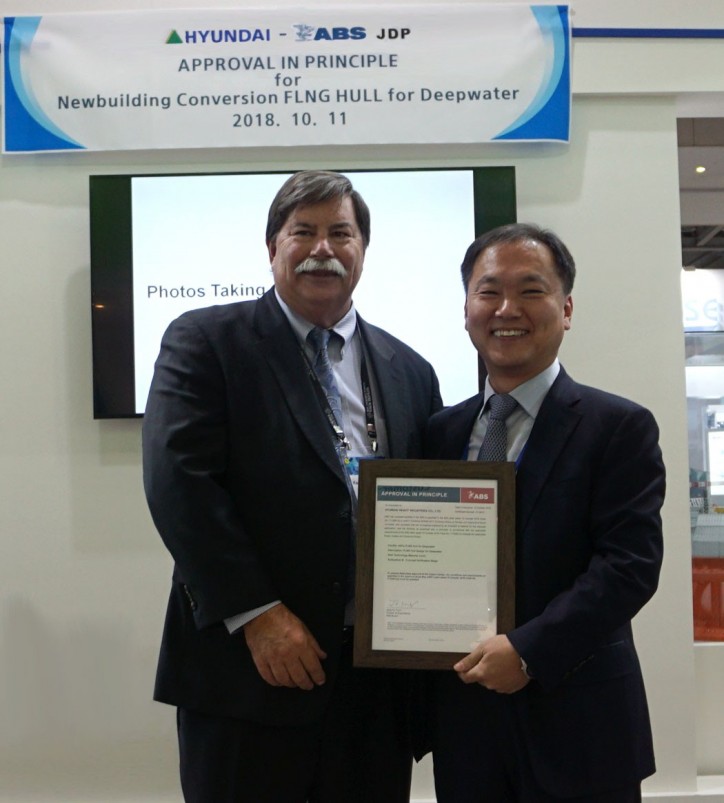

ABS granted Approval in Principle (AIP) to Hyundai Heavy Industries’ (HHI) Deepwater Floating Liquefied Natural Gas (FLNG) hull design.

HHI advises the Newbuilding Conversion FLNG hull design for offshore application can be constructed for about 80 percent less than the cost of a conventional FLNG hull. It is based on LNG carrier designs combined with the requirements for FLNG production, such as structural reinforcements to take topside module load and a hull designed to allow up to 25 years operation without dry-docking.

“ABS is the market leader in the classification of offshore drilling and production units, including FLNG vessels, with more than 150 floating oil and gas facilities in the ABS-classed fleet,” said ABS Vice President Global Gas Solutions, Patrick Janssens. “We have partnered in leading innovation in the offshore sector for 60 years, and we are proud to enable this latest advanced deepwater FLNG Hull approach from HHI.”

HHI developed a technically feasible FLNG hull approach, combining the latest industry trends with first-class shipbuilding practices and ABS rules, maintaining high safety standards. A low cost Near Shore FLNG Hull was successfully developed and achieved ABS AIP in 2017. The same team from HHI and ABS has now worked to deliver this harsh environment Deepwater Hull to meet increasing market demand.

“In the current emerging gas market, a ready-to-convert offshore FLNG hull, with ABS certification, at affordable CAPEX is an important product for monetization of gas reserves around the globe. This new line-up from HHI responds to the requirements of operators and combines HHI’s unparalleled expertise in shipbuilding with ABS’ stringent safety evaluation,” said Hyungkwan Kim, Executive Vice President, Shipbuilding Division at HHI.

The design features a Barge-shaped Hull, a GTT Mark III containment system with storage for about 192,000m3, and provisions to accommodate an internal turret and 45,000-ton of topside modules to deliver 2.5 MTPA of LNG.

ABS has been the preferred classification organization for the offshore and energy industry for more than 60 years. ABS has been integral to the evolution of gas development with a long history of working with floating gas concepts: classing the first offshore LPG storage facility in the mid-1970s, the first purpose-built LPG floating storage and offloading unit, delivered in 1997, and the first LPG FPSO in 2005. In 2018, PETRONAS selected ABS to class the newbuild PFLNG 2 which will operate on the deepwater Rotan gas field offshore Sabah, Malaysia.

Source: ABS