Havyard is taking the next step towards a hydrogen system pilot for large ships. The company is entering the approval phase and has signed agreements with providers of hydrogen tanks and fuel cells.

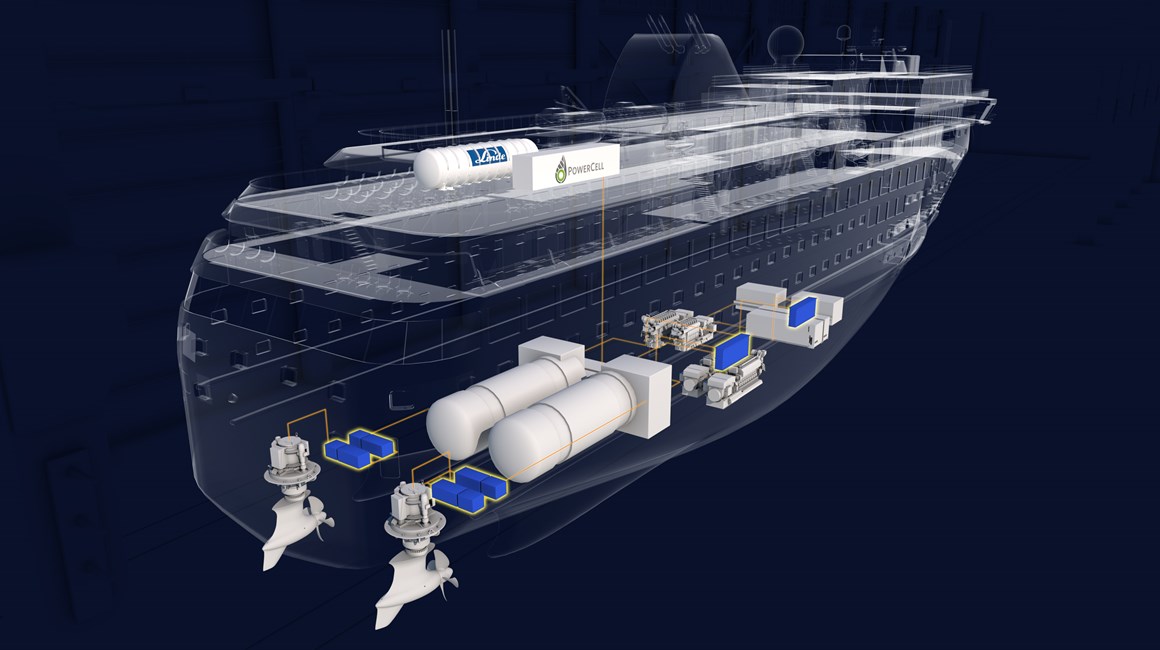

If large vessels are to sail zero-emission at high speed over long distances, battery solutions do not contain enough energy. Fuel cells running on hydrogen is a solution to this, and the Havyard Group, with Havyard Design & Solutions and Norwegian Electric Systems, is now conducting pioneering work on the development of a system that will become the biggest of its kind for ships.

The first phase of the Havyard Group’s ground-breaking work is completed, and the company is now entering into the approval stage for the hydrogen system together with Linde Engineering as tank supplier and PowerCell Sweden AB as supplier of fuel cells.

The project manager for the Havyard Group’s FreeCO2ast project, Kristian Osnes, says Linde is a significant player in the market for designing and manufacturing equipment for cryogenic gases.

We believe they are the right partner for finding solutions that will ensure safe storage and control barriers for cryogenic hydrogen on board ships. The regulations for these solutions have not yet been developed, and we are pleased to have Linde on-board when entering the approval process, which we expect to be very challenging.

The Havyard Group has chosen PowerCell to deliver fuel cells.

PowerCell's core technology for fuel cells is well documented through their cooperation with Bosch for the car industry, and we are looking forward to working with them to create the right solutions for the maritime sector.

Kristian Osnes says that fuel cells have similarities with the battery technology that NES has already worked with in a number of ferry projects, he therefore thinks the cooperation will provide high quality maritime solutions, as they take the zero-emissions goal one step further – from battery to hydrogen.

A comprehensive solution that works

The agreement entails that the Havyard companies, together with PowerCell and Linde, will design a hydrogen solution and take the first step towards certification. This solution will be offered to Havila Kystruten for retrofitting.

This encourages us to have a comprehensive solution in mind from the start. We will deliver a system that is safe, that takes up little space, that is easy to retrofit and, of course, that does the job.

The development of the hydrogen system is part of a PilotE project in which the Havyard companies and the research institutions Sintef and Prototech are working together

Zero emissions also over long distances

The head of research and development at Havyard Group, Kristian Voksøy Steinsvik, says PilotE is very useful when it comes to simplifying the application process in relation to the range of Norwegian research and development funding instruments, and not least in terms of the support, which lessens the risk inherent in spearheading the development.

With PilotE on the team, you can dare to be a first mover at the same time as having a broad focus on developing tools and methods that will benefit both us and the industry, regardless of the type of technical solution we land on.

Havyard Design and Solutions has sound experience of simulation tools and virtual prototyping of ships. This combined with Norwegian Electric Systems’ expertise in green technology and integration will ensure optimal interaction with the other power systems on the ship.

The interaction will provide us with experience to deliver complete hydrogen solutions for several types of ships. The system we are developing is designed in modules and can be installed both in newbuilds and retrofitted in existing ships. In this way, we will contribute to development of large-scale vessels that can sail emission free over long distances, or significant emission cuts from vessels that use hybrid propulsion systems.

Source: Havyard