ABB’s Azipod® propulsion will help Global Mercy™ enter less accessible harbors off the African coast, while reducing vibrations and noise – crucial to the comfort of up to 200 patients and medical personnel on board.

With about 5 billion people lacking access to surgical care globally1, international charity Mercy Ships uses hospital vessels to provide surgeries and medical assistance for free to people who have little access to healthcare. The newest Mercy Ships vessel, the world’s largest purpose-built civilian hospital ship Global Mercy, has been delivered by Tianjin Xingang Shipyard in China during an official ceremony held on June 24, 2021. Global Mercy is equipped with two Azipod® propulsion units, as part of a comprehensive scope of electric, digital and connected solutions to optimize operation.

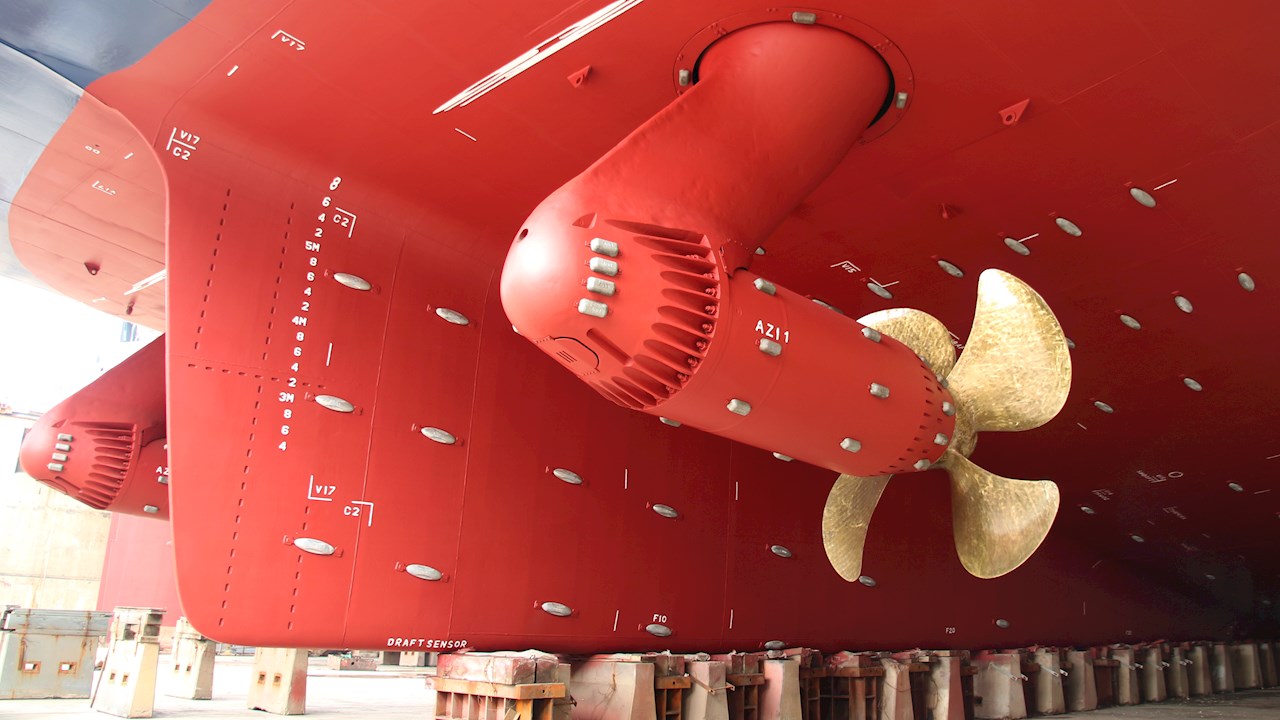

Renowned for its superior maneuverability enabled by 360-degree rotation, the Azipod® system will help the 174-meter ship to navigate through narrow passages and dock in shallow harbors, which are less accessible to other vessels. With many African ports being too shallow for large ships, and with limited or lacking tugboat availability, this feature of Azipod® propulsion will prove crucial for Global Mercy’s ability to deliver healthcare to those in need. Additionally, the Azipod® system’s pioneering design minimizes noise and vibrations, ensuring a smoother, quieter stay for patients and crew on board.

Specially designed by Deltamarin, with Stena RoRo responsible for vessel specification and project management, Global Mercy will feature six operating theatres, hospital wards for 200 patients, general outpatient facilities, ophthalmology and dental clinics, and its own laboratory. The vessel is expected to embark on its first medical air mission to sub-Saharan Africa in 2022, joining the charity’s existing vessel Africa Mercy and thus more than doubling the capacity of Mercy Ships to provide free healthcare.

“As well as offering comfort levels equivalent to a high-quality cruise vessel, hospital ships must provide surgical procedures on the basis of need, making it critical that vibrations are kept to a minimum,” said Per Westling, Managing Director, Stena RoRo. “In sea trials, the performance of ABB’s Azipod® propulsion was even better than anticipated, exceeding expectations on safe return to port and offering smooth and closely controlled sailing.”

“Global Mercy will change the lives of people who would otherwise have no access to high-quality healthcare, and we are honored to be involved in such a remarkable project,” said Juha Koskela, Division President, ABB Marine & Ports. “We are confident that the performance of Azipod® propulsion will contribute to the safe and successful provision of medical care on board and allow Global Mercy to support people in areas that would otherwise be too challenging to access.”

Arriving at the yard fully assembled, the Azipod® system is considerably easier to install than a traditional shaftline propulsion, plugging straight into the vessel’s hull.

“Ease of installation of the Azipod® propulsion system has been a decisive factor, as well as our previous successful collaboration with ABB on other passenger vessel projects,” said Mr. Haibo Mao, Construction Leader of Tianjin Xingang Shipyard.

In addition to the twin 2.85-megawatt (3,821 HP) Azipod® units, ABB’s scope includes generators, switchboards, transformers and drives, as well as bridge controls for the propulsion system and the ABB Ability™ Marine Remote Diagnostic System, which allows the prompt detection and correction of faults on board.

Once in operation, Global Mercy will receive round-the-clock support from ABB Ability™ Collaborative Operations Centers, which serve over 1,000 ships worldwide. From these hubs, ABB experts monitor shipboard systems, coordinate equipment diagnostics, and offer predictive maintenance services, offering global 24/7 technical support. This support is essential for floating hospitals, which require the highest standards of safety and reliability.