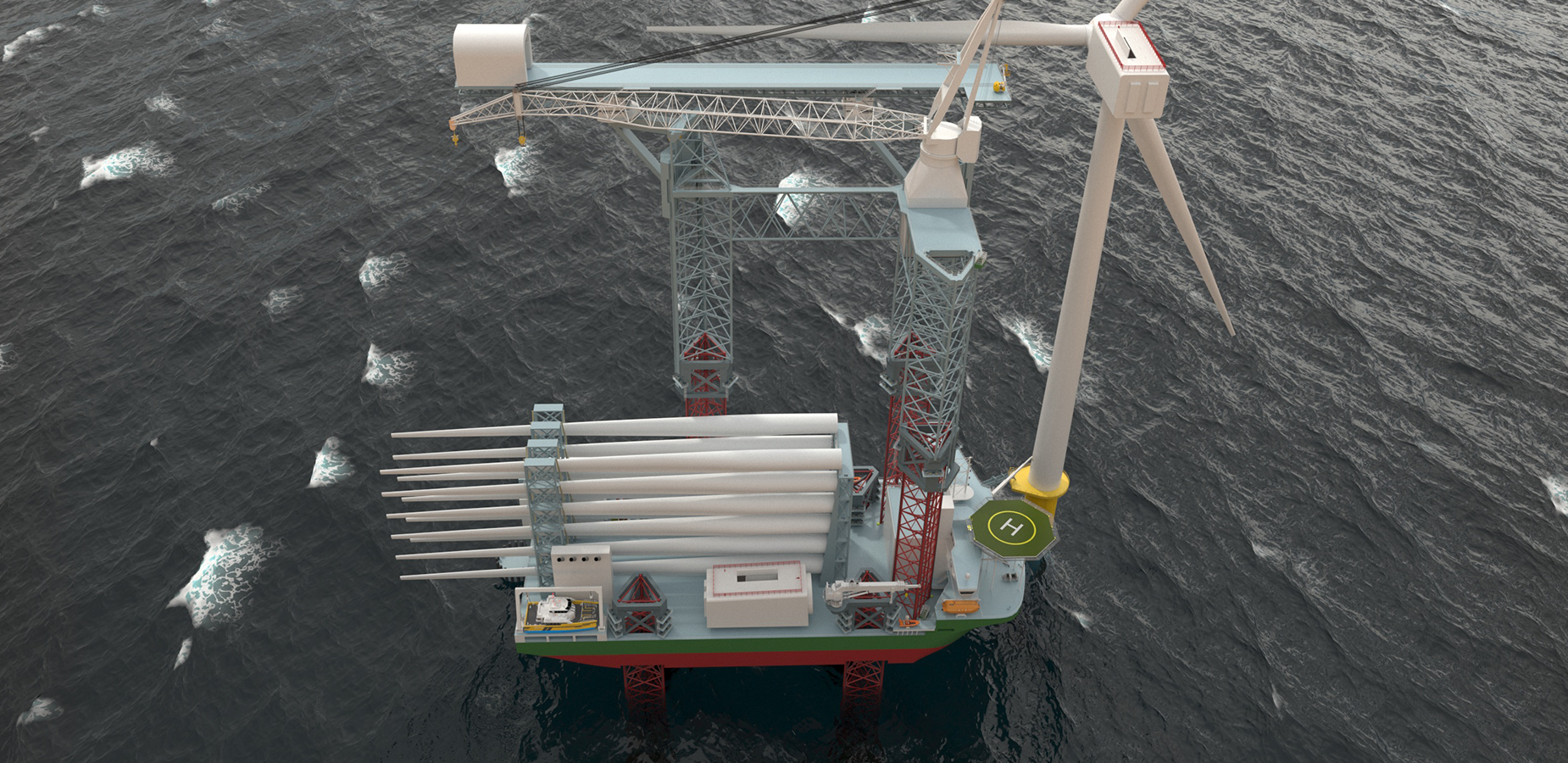

KNUD E HANSEN continues to expand its portfolio of innovative designs and extensive experience in the offshore wind farm sector with a new wind turbine maintenance platform – The “Jack-up on Jack-up” concept.

This four-legged jack-up vessel features a 15 m wide working platform, which can be elevated to the height of the nacelle, thus providing a safe platform for maintenance work on the blades eliminating the need for hazardous rope access.

With a telescopic weather cover fitted on the platform, work on the blades can be done in practically all weather conditions, day or night, resulting in far more working hours annually than with conventional maintenance vessels and rope access, making it possible to set up a dependable schedule for planned maintenance.

A large, air-conditioned workshop is located at the aft end of the work platform, and when the weather cover is deployed, a virtual factory hall is created around the blade, allowing all types of work to be performed on the blade, minimizing the need to remove the blades and transport them to shore for repair. Additionally, with the possibility of inserting an X-Y motion compensating system between the work platform and the platform carriers, the “factory hall” can remain geostationary.

A “cherry picker” mounted on a hammer head at the platform’s opposite end provides the access to the nacelle.

The main crane is fitted on the elevating structure, allowing for the use of a conventional pedestal-mounted crane with a boom that is approximately 30% shorter than that of a conventional wind turbine maintenance vessel, which should be able to reach the same height, providing a much better view of the blades and the nacelle from the crane driver’s cabin.

Measuring 154 m in length and 64.4 m in breadth, this vessel is designed for all kinds of maintenance work on wind turbines up to 20 MW, including replacement and handling of nacelles weighing as much as 1,000 t at a hub height of 175 m, and managing blades up to 130 m long. This can be done while it is jacked up in 80 m water depth.

Two crew access vessels are arranged in davits on the aft deck, and with a retractable boat landing that can reach the water when the vessel is jacked up, the vessel can work as a mother vessel for CTVs working in the area.

This innovative design is currently patent pending for the “Jack-up on Jack-up” concept, with the elevating work platform, and its unique suspension allowing it to be positioned precisely beneath a turbine blade, and with regard to the weather cover.