Hyundai Mipo Dockyard (HMD) is scheduled to deliver the world’s first ballast free LNG bunkering vessel later this year. The 7,600m³ vessel was ordered by Germany-based Bernhard Schulte Ship management in late 2016 and is currently under construction to LR class at HMD’s Ulsan shipyard.

Since the introduction of steel-hulled vessels, ballast water has been essential for the safe and efficient operation of vessels, but it also poses an ecological, economic and health threat because of the increased number of species that could be moved from one place to another. With the entry into force of the IMO’s Ballast Water Management Convention in September 2017, all ships constructed (keel lay date) on or after this date, to which the Convention applies, will now be required to be fitted with a ballast water treatment system at delivery. HMD is looking to address this problem through the development of this vessel without the need for a ballast water treatment system.

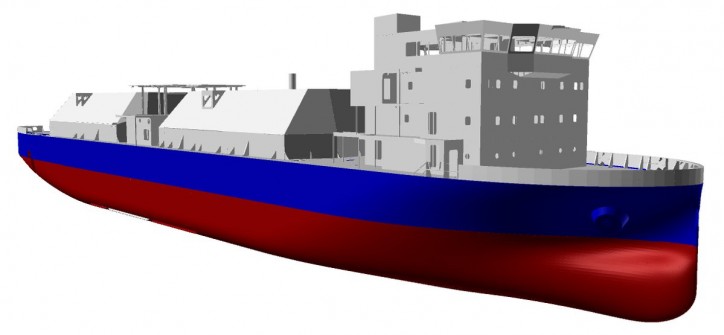

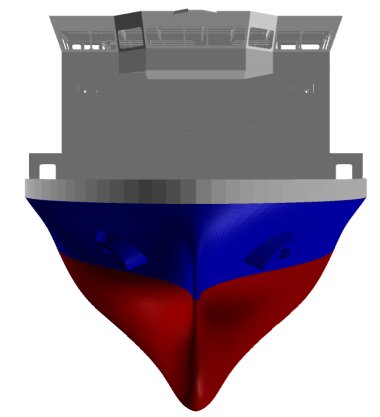

To apply the ballast-free concept to this vessel design, HMD gave careful consideration to the special hull form with dead-rise; forward ‘engine room and deckhouse’ and a twin propulsion system with azimuth thrusters so that the vessel can retain its damage stability and easily control the trim and heel without ballasting.

HMD’s first obstacle was the speed management by dead-rise. In general, dead-rise is known to help improve the ship’s stability, which is critical to this ballast-free vessel, but it is also likely to deteriorate the vessel’s speed performance. To counteract this, HMD focused heavily on the hull form optimisation and successfully developed a better performing dead-rise hull form, confirmed through the wet model test.

HMD’s first obstacle was the speed management by dead-rise. In general, dead-rise is known to help improve the ship’s stability, which is critical to this ballast-free vessel, but it is also likely to deteriorate the vessel’s speed performance. To counteract this, HMD focused heavily on the hull form optimisation and successfully developed a better performing dead-rise hull form, confirmed through the wet model test.

Another key feature of this vessel that enables it to be ballast-free is the twin propulsion system with two azimuth thrusters. The smaller diameter of propellers fitted in the azimuth thrusters enables the vessel to achieve full immersion in all operational conditions.

LNG will be stored in two independent IMO type C tanks which are designed to contain the LNG with a minimum temperature of minus 165° C and maximum vapour pressure of 3.75 bar(g), and can be transferred to an LNG-fuelled vessel at the rate of about 1,250m³/hour through the cryogenic flexible hoses without ballasting and/or de-ballasting operation. Additionally, the natural vaporising gas from the bunkering vessel and the returned boil-off gas from the LNG-fuelled vessel will be compressed up to 220 bar(g), stored in two sets of 40 feet container and used for propulsion fuel and electric.

Seung-Ho Jeon, SVP of HMD Initial Planning Division, said: "The ballast-free concept will be made a reality by the technology expertise of HMD. We aim to stand out in the field of eco-friendly business practice."

Jin-Tae Lee, Ph.D, LR’s Korea Chief Representative & Marine Manager, a great supporter of technical innovation, said: "We are delighted to work with the shipyard helping the marine industry bring innovative designs to the market. We believe that this design is another remarkable development for HMD to realise the industry’s need for safe, efficient and clean requirements in the shipping industry worldwide."

The ballast-free concept means that the vessel will not need to install a ballast water treatment system and it also removes the need to comply with the Performance Standard for Protective Coatings for ballast tanks and related regulation, enabling maintenance costs savings.

Source: LR