Alewijnse Marine has won the contract for the electrical fit-out of two additional Damen Combi Freighter 3850s currently in build at Damen Yichang Shipyard for delivery in January 2020.

The scope of the contract is based around the design, build and delivery of the main and emergency switchboards that form the core of the vessels’ electrical systems including those for alarm monitoring, fire alarms and public address. Alewijnse personnel will also oversee the installation and commissioning of the systems undertaken by the yard’s technicians. With the Combi Freighters having been built in series for stock since 2000, the emphasis of the project is on maximum efficiency and the continuous improvement of the build process, which takes about a year for each vessel.

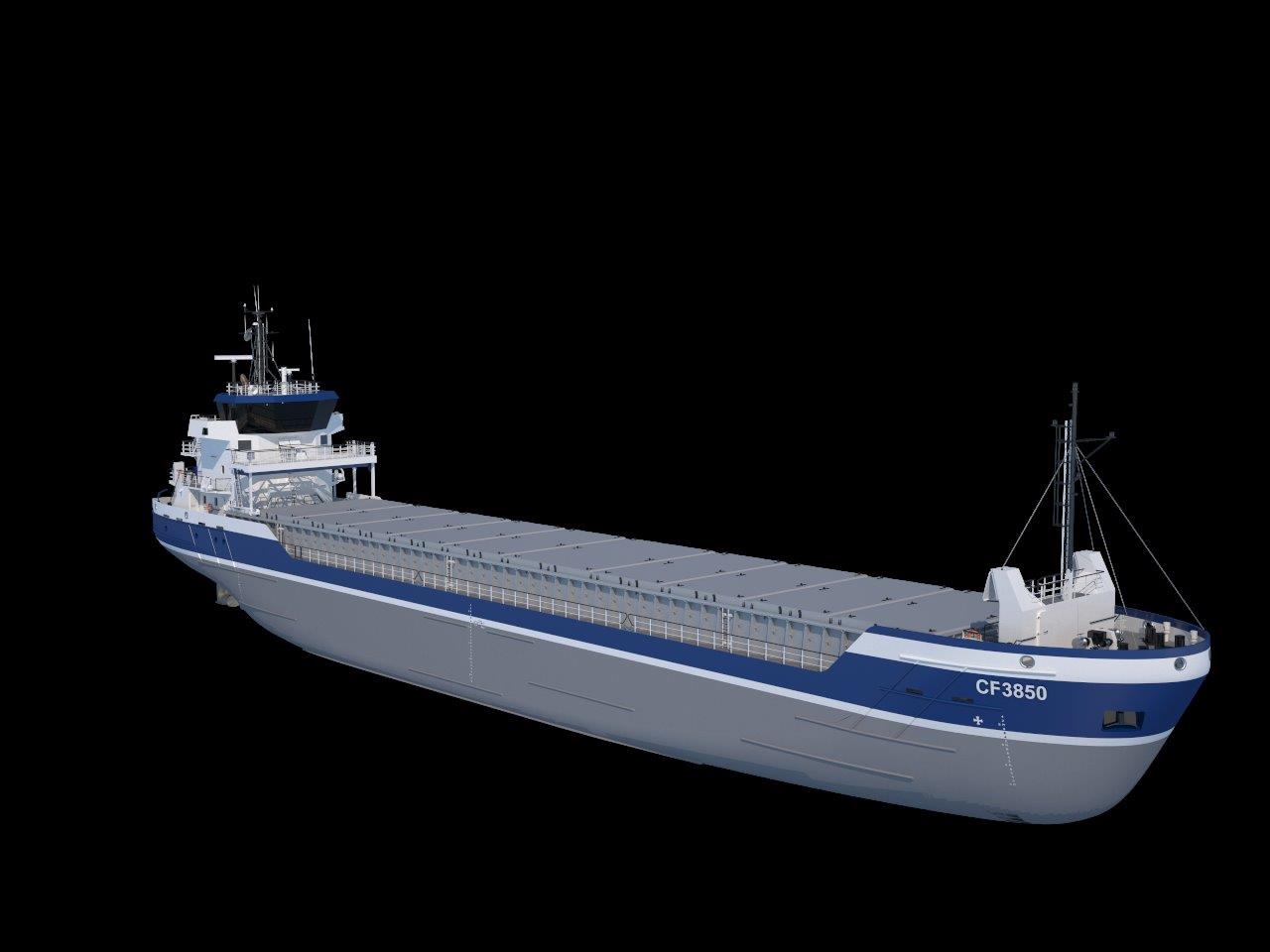

Damen’s Combi-Freighter range is comprised of eco-friendly, sea-going, multi-purpose cargo vessels that combine high capacity with low operating costs. Available with a wide range of standardised options they can be adapted for almost any role. The 3850 is 90 metres in length and has a DWT of 3,800 tonnes.

Richard Nugteren, Product Director Shipping at Damen, said; “We chose Alewijnse for this latest project as it is a Dutch supplier that shares our commitment to quality and it is highly experienced in the fit out of the Combi Freighter 3850. Since its introduction, Damen has built around 60 of which Alewijnse has worked on approximately 56.”

“We have collaborated with Damen Shipyards Galati (DSGa) since its start in 2001 and become more involved with the wider Damen Group over the years that have followed,” added Petrica Craciun, sales manager at Alewijnse Marine Galati. “We now deliver electrical installations for Damen vessels ranging from tugs to patrol ships, support ships and the Australian Antarctic Supply Research Vessel currently in build. We have an excellent working relationship with the group and have fine-tuned our services to meet their exact needs. We contribute to the projects through our experience and focus on efficient design and execution. We set out to minimise total cable length and implement best practice on all phases of the design process. As an international company we also provide a short supplier chain from producer to user which contributes to keeping the project costs on budget.”

With the order confirmed, Alewijnse Project Manager Ionut Melescanu and his team have now begun the engineering and material purchasing phase.

Source: Alewijnse