Alliance between Siemens Drilling and Marine, Dresser-Rand—A Siemens Business, and Lloyd’s Register provides end-to-end solution to guarantee availability of LNG as marine propulsion fuel.

“The innovative solution to this industry hurdle includes the entire supply chain from liquefaction, LNG bunkering and design, all while meeting EPA and USCG compliance and providing smart, sustainable, lower greenhouse gas alternative fuels to operators.”

Siemens Drilling and Marine, Dresser-Rand—A Siemens Business (D-R), and Lloyd’s Register (LR) announced a best of industry team to make LNG widely available to ship owners seeking to use natural gas as a propulsion fuel, meeting tough Sulfur (SOx) and Nitrogen Oxide (NOx) emission-reduction requirements – whether regionally or globally.

By providing an end-to-end solution encompassing the entire supply chain from natural gas procurement to liquefaction and delivery of LNG to new-building or retrofitting, the collaboration will remove obstacles that can hold back wide-spread adoption of natural gas as the marine fuel of choice.

According to Lloyd’s Register, there are approximately 40-50 LNG-fueled vessels globally, but strong growth is predicted. Much of this proposed growth is driven by increased emissions regulations, including stringent EPA compliance requirements for marine customers operating across the North American Emissions Control Area.

David Grucza, Siemens Drilling and Marine, explains, “In putting together this team of leaders in the marine and LNG space, our integrated solution, encompassing the entire supply chain of LNG including gas-fueled marine propulsion systems, will remove the chicken-and-egg hurdle from the LNG-equation. This is a disruptive concept for the maritime industry, and the technology exists for immediate adoption. This joint solution is not limited geographically, and we stand ready to support the marine industry globally, although our initial focus is on deploying U.S. shale gas.”

The initial end-to-end solution offered to the North American inland and coastal waterways community comprises the following elements designed and engineered by leading naval engineering firms Waller Marine Inc. (WMI) and The Shearer Group Inc. (TSGI), respectively, and will be constructed by Conrad Industries shipyard in Texas:

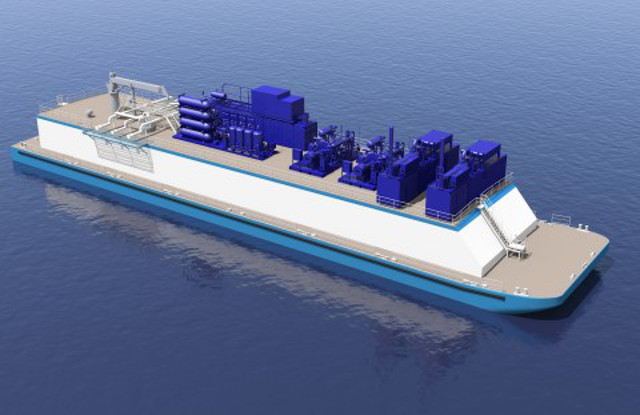

- Land-based and/or floating, LNGo™-liquefaction barge;

- LNG bunkering barge (C-Type tanks with up to 2,500 m3 capacity);

- and 4,200 or higher horsepower river Pushboat.

“Together, the team brings a holistic answer to the LNG marine fuel question of what comes first – the bunkering station or the engine?” says David Waller, President, Waller Marine, Inc. “The innovative solution to this industry hurdle includes the entire supply chain from liquefaction, LNG bunkering and design, all while meeting EPA and USCG compliance and providing smart, sustainable, lower greenhouse gas alternative fuels to operators.”

“Lloyd’s Register is well placed to support a new fleet of gas-fueled ships – and help them to operate safely and efficiently. Our expertise and leadership in gas technology and operations – from gas carriers to LNG bunkering and gas as a marine fuel – helps lead to the best decisions based on the best, independent, technical insight,” said Mark Darley, Americas Regional Marine Manager and President of Lloyd’s Register North America (LRNA).

Lloyd’s Register has established clear standards describing different levels of readiness to use natural gas as a marine fuel. Lloyd’s Register also provides training on the key practical aspects of modern LNG carriage by sea and risk management services to support safe LNG bunkering.

Source: www.businesswire.com