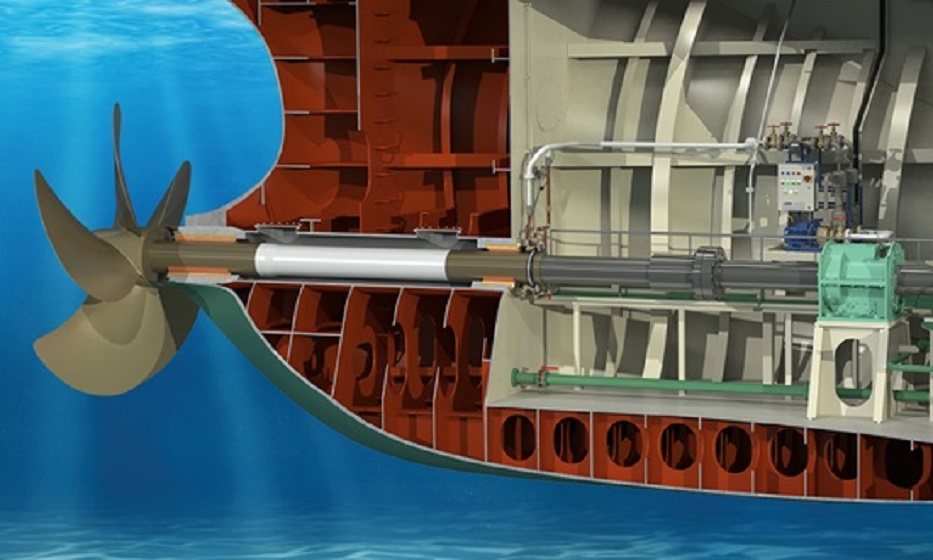

Nippon Kaiji Kyokai (ClassNK) has joined the major classification societies to amend its rules relating to the inspection of seawater-lubricated propeller shaft systems.

The amendment means that ships with open seawater-lubricated propeller shafts that are built to ClassNK rules are subject to the same 15-year shaft withdrawal inspection periods as oil-lubricated shafts and sterntubes, subject to monitoring criteria.

The announcement brings ClassNK’s requirements in line with those of other large class societies, including Lloyds Register (LR), the American Bureau of Shipping (ABS), Det Norske Veritas (DNV), Bureau Veritas (BV) and the China Classification Society (CCS), which have already stipulated 15-year or longer intervals between inspections, some of them since 2016.

In its amendments to the Rules and Guidance for the Survey and Construction of Steel Ships, published on 30 June 2023, Class NK clarified its reasons for the change: “In recent years, the development of mechanical type sealing devices, and bearings with lower wear properties as well as improvements in corrosion prevention technology, have led to fewer wear and corrosion defects in both shafts and bearings. In addition, interest in seawater-lubricated bearings, which do not use lubricating oil, and their effectiveness has increased among relevant industry members due to concerns for the environment.”

ClassNK also noted that the amendment follows requests received from industry stakeholders relating to the developments made in advanced seawater-lubrication system technology.

Thordon Bearings is one of the companies that has supported calls for industry-wide standardization of extended shaft withdrawals for seawater-based lubrication solutions that are now comparable to sealed oil lubricated systems.

Craig Carter, Vice President of Business Development, Thordon Bearings, said: “We are delighted that ClassNK has now joined the other major classification societies in dispensing with the wholly unnecessary and costly need to withdraw a seawater-lubricated propeller shaft for inspection every five years. Technology has come a long way since the first-generation seawater-lubricated lignum vitae bearings of the 1950s.”

While the risk of shaft corrosion in open seawater-based systems was historically a concern with first-generation bearings, leading some classification societies to continue demanding enhanced inspection regimes, new materials and technologies mean seawater-based systems can exceed the performance and reliability of their oil-based counterparts.

Elena Corin, Senior Manager, Special Marine Projects, Thordon Bearings, explained: “Aside from our pioneering polymer bearing technology, Thordon has enabled the development of Thor-Coat - a toughened, modified epoxy coating, which is applied to exposed steel areas of the shaft between the liners to eliminate the need for shaft withdrawal. In the event of damage, seawater cannot wick under the coating along the shaft and the epoxy coating is spot repairable.”

As the global leader among seawater-lubricated propeller shaft bearing manufacturers, Thordon Bearings has concentrated over 40 years of research and development to produce a solution proven to be more in line with the decarbonization movement of the 21st century than its antiquated oil-lubricated cousin.

“It is undeniable that the increasing number of ocean-going tankers, bulkers, dry cargo vessels, passenger ferries, cruise ships and containers that now routinely specify a Thordon propeller shaft bearing are significantly more environmentally and operationally efficient than their oil-based equivalents,” Corin said. “Thordon’s COMPAC open seawater-lubricated propeller shaft bearing system ensures zero environmental impact, improves fuel efficiency and eliminates the costs associated with managing oil discharges.”

In addition to the amendment regarding the inspection of seawater-based propulsion systems, Class NK has also updated several other requirements. These include new formulae for sloshing loads and new requirements for the maintenance and management of offshore wind turbine installations. Other changes include clarification of scope for protection against fire when transferring cargo to other vessels on liquefied gas carriers, clarification of the NOx emission standards for biofuel, new requirements for cast and forged steel products, and amendments to safety requirements for reciprocating internal combustion engines.

Delegates at an international water industry conference learned that bearing selection plays a critical role in vertical turbine pump (VTP) performance, and that application, medium and bearing material should also be considered during pump manufacturing or refurbishment.

“The selection of the most appropriate material for bearings is one of the most important factors affecting pump reliability,” Thordon Bearings’ Strategic Account Manager, Keith Brand told attendees at Water Expo 2023, which took place last week at the Miami Airport Convention Centre.

In his paper Selecting the Right Bearings to Improve Vertical Turbine Pump Reliability, Brand informed industry leaders that “…the nature, particularly the abrasiveness, of the pumped media, is a key variable affecting optimal pump bearing selection and lifespan.” The other key variable, he said, is application. “Abrasive wear and dry starts are the most common causes of bearing failure.”

Taking a deep dive into common oil and water-lubricated bearing materials, such as bronze, carbon graphite, thermoset laminates, Teflon®, thermoplastics and elastomers, Brand explained that they all have their pros and cons. Some bearings have better dry-running capability but poor abrasion or chemical resistance, while others may be better suited to high-temperature environments but fall short on mechanical strength. All tend to be more costly in terms of OPEX.

“In some applications the upper bearings are not lubricated upon start up. This could mean thirty seconds or more of high-speed dry bearing operation, completely ruling out certain materials, such as rubber,” continued Brand.

“Rubber bearings can burn up from frictional heat created with little to no lubricant and most phenolic bearings cannot handle running dry for more than sixty seconds. Here, oil-lubrication or a water flush is required to lubricate the bearings until process water can lubricate the shaft, but this also adds to the cost and can be detrimental to the environment,” he said.

Brand furthered that some manufacturers have attempted to make pump components more chemical and abrasion resistant by isolating the pump’s oil-lubricated bearings and shafts from process water. “But the biggest drawback to this approach is the additional cost,” he said.

Going on to explore the different types of water-lubricated/grease-free polymer bearings available from the Thordon portfolio, Brand explained that Thordon has a range of products to meet the demands and challenges of many types of operating mediums and applications.

For example, the company’s Composite bearing material, an elastomeric polymer alloy, is specially designed for use in highly abrasive operating environments. The SXL material on the other hand balances the operational requirement between abrasion resistance, low friction and good dry start up performance. Meanwhile, Thordon’s ThorPlas-Blue, an engineered thermoplastic, has excellent chemical resistance and can also handle dry starts and operate at higher temperatures. ThorPlas-White has the same great qualities as ThorPlas-Blue, but it is designed specifically for food equipment, drinking and potable water applications and has NSF/ANSI 51/61 and WRAS approval.

The paper goes into much more detail with a useful and informative Thordon material selection guide, showing the grades recommended for VTPs, with direct comparable reference to the key variables such as temperature limits, abrasion resistance, shaft material compatibility, pumping media limitations, dry start capabilities and more.

Summing up, Brand told Water Expo delegates that while there is no single correct answer to bearing selection, understanding pumped mediums and dry startup requirements will narrow down the options. “Ultimately, understanding bearing material selection will keep pumps pumping longer, reduce downtime and maintenance costs, and prevent catastrophic failure,” he said.