Keppel Offshore & Marine Ltd (Keppel O&M) has delivered the 6000m3 Trailing Suction Hopper Dredger (TSHD) Sanderus to Jan De Nul Group safely with zero lost time incidents. The Ultra-Low Emission vessel (ULEv) is the fourth dredger that Keppel O&M has delivered to Jan De Nul Group.

This follows the delivery of three 3500m3 TSHDs earlier this year, all ULEvs and the world's first European Union (EU) Stage V dredgers. Keppel O&M is also currently building Ortelius, a 6000m3 dredger which is identical to the Sanderus, for Jan De Nul Group, with delivery expected in 1Q 2020.

Mr Tan Leong Peng, Executive Director (New Builds) of Keppel O&M, said, "We are pleased to support Jan De Nul's strategy of building Ultra-Low Emission dredgers. Having delivered four of this type of dredgers, we have developed strong competencies and cost-efficiencies in this market. As customers pursue greener operations, we are able to leverage our newbuild capabilities to adapt and provide value added solutions. We look forward to the delivery of the next dredger, which will further strengthen our track record in the non-oil and gas segment."

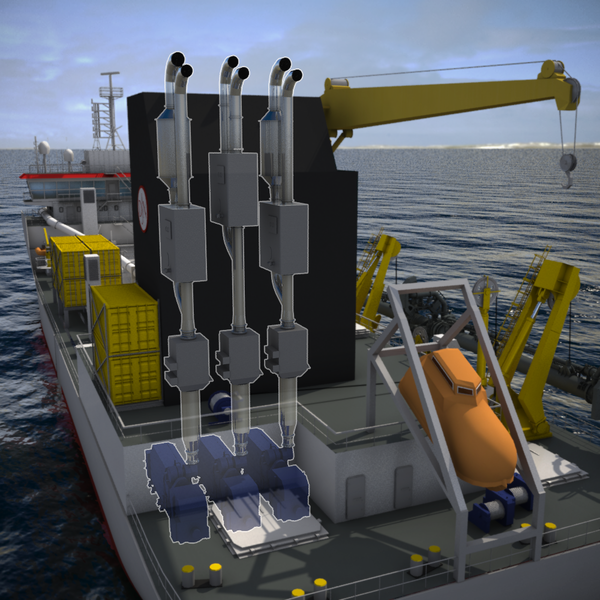

Sanderus is fitted with a two-stage filtering technique for exhaust gases. It complies with the EU Stage V and International Maritime Organisation's (IMO) Tier III regulations.

Mr Robby De Backer, Director of Newbuilding Department of Jan De Nul Group, said, "Like all our new dredgers, Sanderus is equipped with a state-of-the-art exhaust gas treatment system that extracts up to 99% of the nanoparticles from exhaust gases. It will enable dredging at the lowest levels of emissions to date. In partnering with industry leader Keppel, we have been assured of excellent service, engineering expertise and reliability in receiving a high quality product safely, on time and on budget."

Sanderus will immediately sail to Belgium for maintenance dredging works on the river Scheldt and alongside the coast.

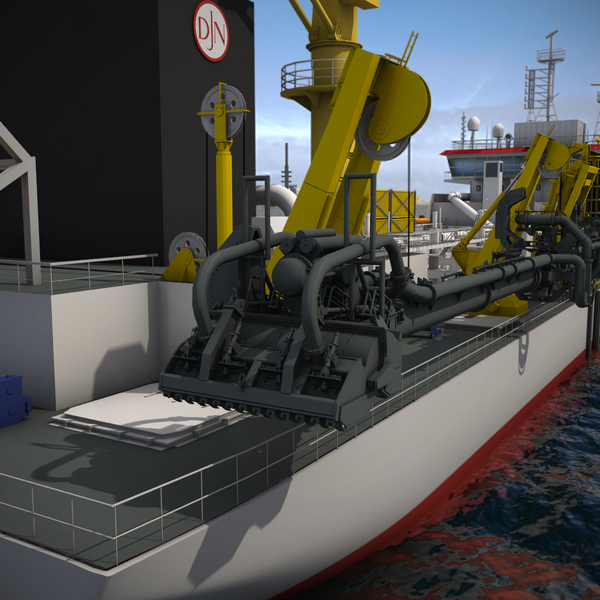

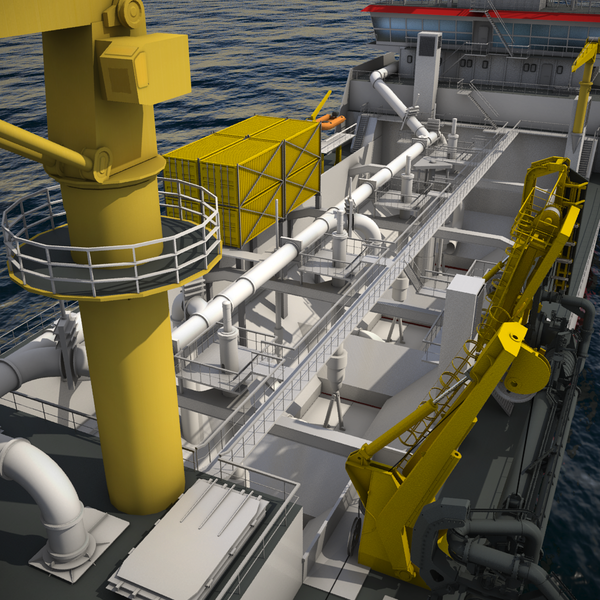

Built to the requirements of classification society, Bureau Veritas, Sanderus is diesel-electric driven and is able to dredge to a maximum depth of 35m. Featuring a shallow draught and high manoeuvrability, it is also suitable for working in confined areas.

TSHDs are mainly used for dredging loose and soft soils such as sand, gravel, silt or clay. The dredged material can be deposited on the seabed through bottom doors or discharged through a floating pipeline to shore and used for land reclamation.

Source: Keppel