The successful SCHOTTEL Rudder EcoPeller (SRE) is set to be installed in a retrofit project for the first time. Two four-bladed SCHOTTEL EcoPellers type SRE 340 L CP with an input power of 750 kW each will be featured in a double-ended ferry from the Norwegian ferry operator Torghatten Trafikkselskap.

Gunnar Heringbotn, Technical Manager at Torghatten Trafikkselskap: "We have already equipped several of our ferries with SCHOTTEL propellers. For the electrification of the 'Torghatten', we have opted for the SRE, as it optimally meets our requirements and supports us on our way to an eco-friendly future. Thanks to the tailor-made modernization concept, downtimes can be kept as short as possible."

Since it is possible to integrate the SCHOTTEL solution into the existing steel structure of the former propulsion system, no hull changes or major steel work will be necessary. Beyond this, the work can be carried out by a local shipyard – thus reducing installation efforts and shortening downtime tremendously.

Fully electric system powering the ferry

Fully electric system powering the ferry

The EcoPellers will be driven by electric motors. In operating mode, the required power will be supplied by battery packs installed on board. These will be recharged from the land grid during the stays on the quay.

SCHOTTEL LEACON sealing system

To be environmentally compliant, the propulsion system of the Norwegian ferry will be equipped with the patented and DNV-GL type-approved SCHOTTEL LEACON sealing system. Through the use of separate seals on the seawater side and on the gearbox side, the sealing system ensures that, in case of leakage, seawater entering the system or gear oil escaping from the system are collected in an intermediate chamber. This prevents water from entering the gearbox and, of even greater importance, oil from escaping into the seawater.

Higher efficiency, lower operating costs

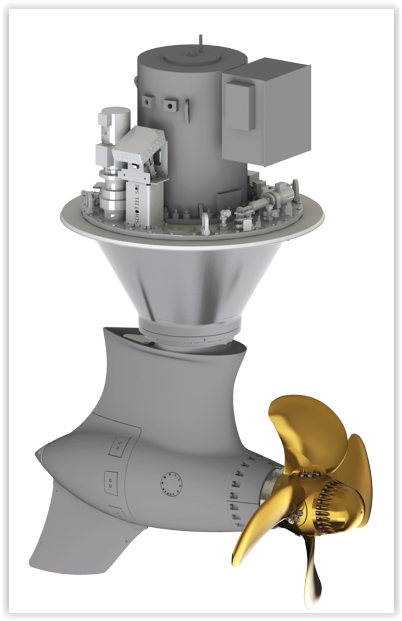

Covering the range from 500 to 5,000 kW, SCHOTTEL EcoPellers ensure high efficiency and improve course keeping stability many times over. The ecologically clean propulsion system has been primarily developed for open seas and coastal operating conditions. By combining proven SCHOTTEL quality with latest technologies, the azimuth thruster contributes to the ship's low fuel consumption, resulting in low operating costs and low emissions.

Figure 2: By combining proven SCHOTTEL quality with latest technologies, the azimuth thruster contributes to the ship's low fuel consumption, resulting in low operating costs and low emissions

Source: Schottel