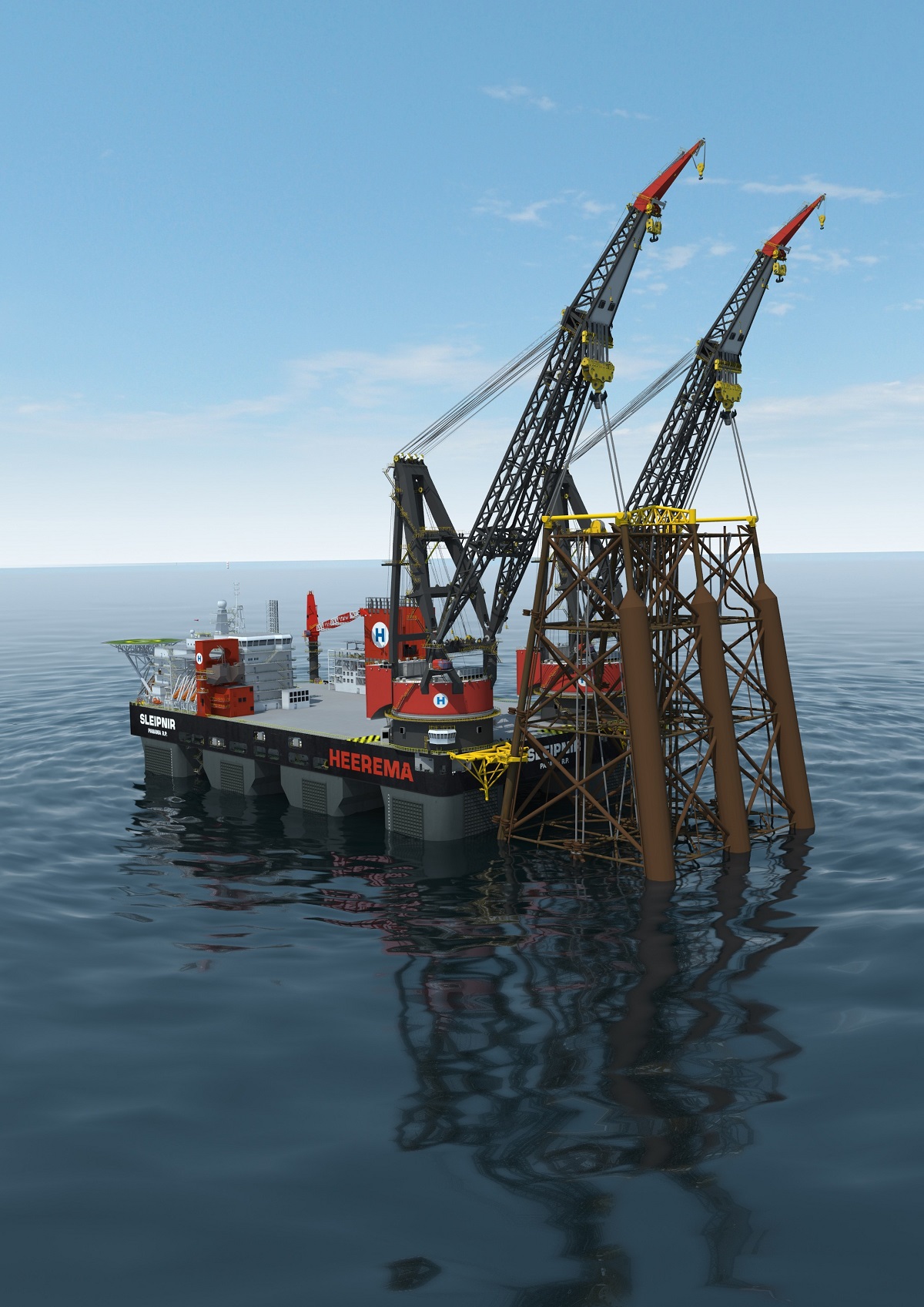

Heerema’s SSCV Sleipnir has safely and sustainably removed Shell’s 10100 mT Brent Alpha jacket. This single jacket lift breaks Sleipnir’s recent record for lifting the 8100 mT Jotun-B jacket.

This project is Sleipnir’s fourth decommissioning job for this summer. The vessel will continue to be busy in the North Sea before swapping the largest lifts for one of the smallest with the installation of Dana Petroleum’s P11-Unity Platform later this year.

So far, Sleipnir has safely removed and transported more than 43900 mT of decommissioned offshore infrastructure for recycling over this summer campaign.

For the Brent Alpha jacket removal, Sleipnir arrived at the Brent Field located 186 km northeast of Scotland’s Shetland Islands on July 23, 2020 and completed the project by offloading the jacket onto the quayside at the AF Miljøbase decommissioning site in Vats, Norway on August 11, 2020.

The Brent Alpha jacket removal presented novel challenges for Heerema, resulting in unique solutions. During the project, Heerema cut jacket legs at 7.3m diameter using a 288” Diamond Wire Cutting Tool developed alongside CUT UK, especially for the Brent Alpha removal - the largest leg diameter to have been cut this way.

Also, during this project Heerema removed and transported the conductors with the jacket, an entirely new way of decommissioning. The conductors were suspended on a Heerema Fabrication Group built Conductor Hang-off Frame made for this project.

Sleipnir is the world’s most sustainable SSCV, and during the project the vessel performed the full removal operations while running on emission-reducing LNG fuel. Using LNG, Sleipnir reduces CO2 emissions by 25%, reduces NOx emissions by 92%, reduces SOx emissions by 99%, and Particulate Matters by around 99% compared to traditional Marine Gas Oil crane vessels.

Now that the Brent Alpha jacket has been safely and sustainably transported to Vats, it will end its lifecycle by being over 97% recycled.

Heerema’s Decommissioning Director, Jeroen van Oosten noted that ‘there were quite some technical challenges during this record-breaking lift. Such as the cutting of the 3 x 288" legs of the platform. However, due to the excellent preparation and perseverance during execution, we successfully delivered this jacket safely and sustainably to Vats for disposal. An outstanding achievement for all involved.’

It is essential to mention that all companies involved followed the strict government guidelines to protect their workforces during the ongoing COVID-19 outbreak. For Heerema, safeguarding our employees and those who work alongside Heerema is always the top priority.

Source: Heerema