The Korean Register (KR) has developed new class rules that completely revise the existing structural rules for membrane-type LNG carriers.

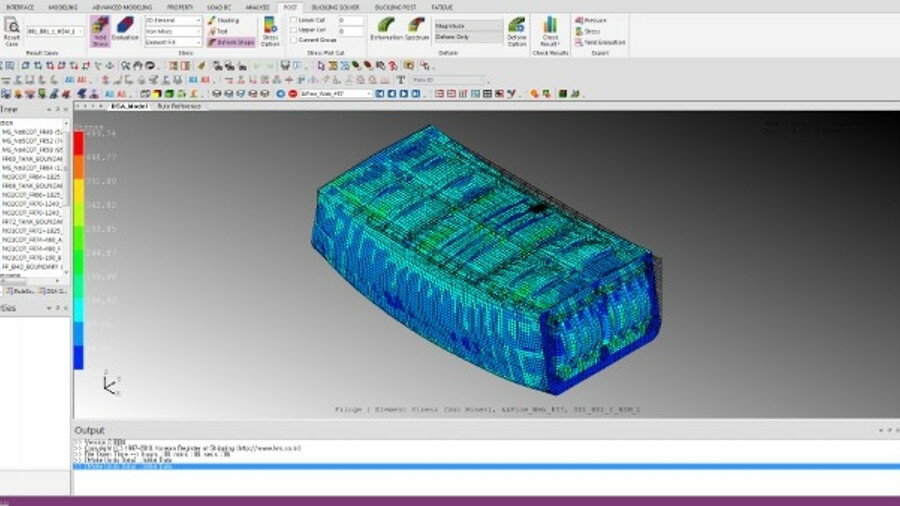

The new class rules apply the concept of EDW (Equivalent Design Wave) based on direct load analysis to determine structural arrangements and scantling that meet the structural strength, buckling and fatigue strength criteria for various load scenarios, and re-verify it by applying direct structural analysis.

The newly developed rules cover not only the general sizes of LNG carrier, but also the ultra-large LNG carriers – the 210,000 to 266,000 m3 (Q-Max) by analysing and reflecting the motion characteristics of these vessels. The new rules have also been developed to fully comply with the IGC Code (International Gas Carrier code).

In order to test and improve the rules, KR has conducted an impact analysis on an LNG carrier working in collaboration with Hyundai Heavy Industries, Daewoo Shipbuilding & Marine Engineering, and Samsung Heavy Industries and applying world-class LNG carrier building technology.

As a result of verifying the rules for the latest design of 170,000 m3 class membrane-type LNG ship, each shipyard also evaluated the rules as highly competitive rules in terms of structural safety and optimized design.

It is anticipated that the structural design time for LNG carriers will be drastically shortened through the inclusion of the new rules in KR's structural scantling and strength evaluation program 'SeaTrust-HullScan', which is already widely used by many design companies and shipyards.

"The new rules for LNG carriers will be applied to membrane-type LNG ships over 150m in length and our LNG technology development work will continue as we work alongside leading shipyards both domestic and abroad, providing the best technical services possible for our LNG customers,” says Kim Yeon-tae, Executive vice-president, Technical Division, KR.

In addition, KR has completed design approval for various types of cargo holds (MARKIII (GTT), No.96 (GTT), KC-1 (KC LNG Tech.), SOLIDUS (Daewoo Shipbuilding & Marine Engineering), SCA (Samsung Heavy Industries), and provides technical services for Type B type LNG carriers and Type C type LNG bunkering vessels as well as for the membrane-type cargo holds.

Source: Motorship