Three new multi-purpose vessels ordered from the Abeking & Rasmussen ship and yacht shipyard (A&R) in Lemwerder by the German government for the Waterways and Shipping Administration (WSV) will be equipped with SCHOTTEL propulsion systems. Planning and design as well as tendering and continuous construction supervision are carried out by the Federal Waterways Engineering and Research Institute (BAW), Ship Technology division.

Maneuverability, high bollard pull, increased availability combined with maximum propulsion efficiency are important for these vessels. These requirements are met by means of two powerful SCHOTTEL RudderPropellers and one PumpJet per vessel. The newly designed A&R vessels will run exclusively on liquid natural gas (LNG).

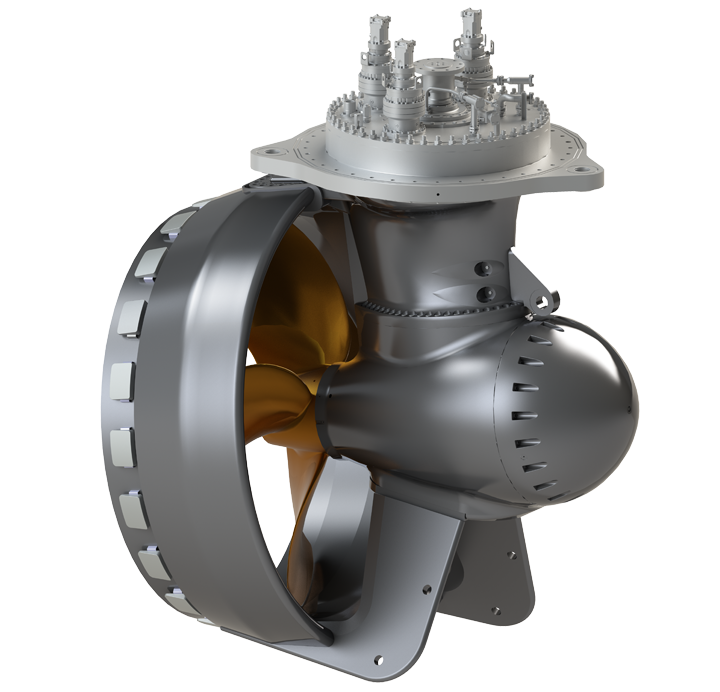

Powerful main propulsion units

Each of the identical WSV special vessels, which are over 90 m long, is driven by two SCHOTTEL RudderPropellers type SRP 750 (each 4,500 kW at 750 rpm). This allows the vessels to reach a speed of over 15 knots and a bollard pull of at least 145 tonnes. With an input power of up to 5,300 kW, the SRP 750 is one of the most powerful rudder propellers in the entire SCHOTTEL portfolio.

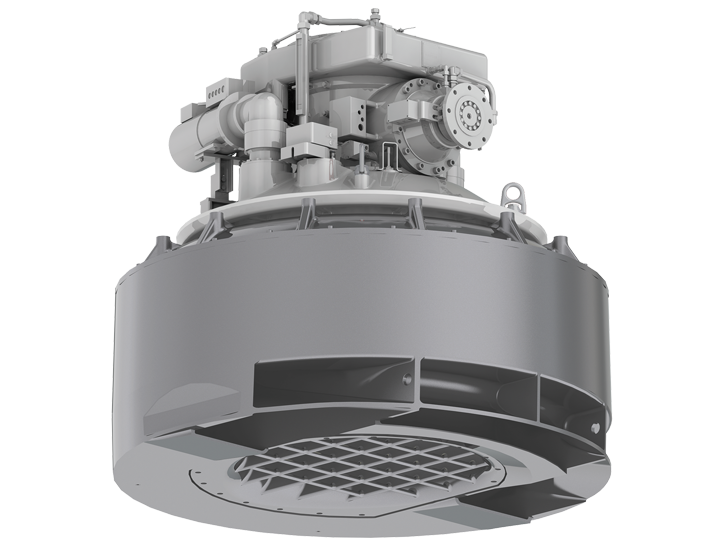

Reliable auxiliary propulsion units

A SCHOTTEL PumpJet type SPJ 520 (2,990 kW) further increases the maneuverability of the vessels and is also suitable for operation in shallower waters thanks to being installed flush with the hull. The SPJ is mounted elastically, which reduces noise and vibration levels on board as well as underwater noise.

Intelligent maintenance for increased availability

In addition, all three vessels will be equipped with SCHOTTEL MariHub, SCHOTTEL's data acquisition and IoT gateway system. It records and analyses signals from sensors, machinery and other components which can then be evaluated by SCHOTTEL for the customer.

With the condition monitoring service ProCMS, MariHub allows for early detection of irregularities in the drive train. This predictive maintenance approach significantly increases the availability of the multi-purpose vessels: ProCMS can reduce maintenance costs and improve maintenance planning.

Safety to the highest degree

The multi-purpose vessels will have special equipment on board, for example a gas-tight “citadel” structure with a protective air supply, in order to carry out operations in hazardous atmospheres such as in the event of shipping accidents. A helipad is located on the foredeck and a winch area is located above the stern. In this way, additional forces and materials can be brought on board the multi-purpose vessels safely.

The tasks of the multi-purpose vessels are manifold and include: working on sea marks, performing waterways police missions, combating pollutant spills and fighting fires, emergency towing within the scope of maritime emergency preparedness guidelines, taking care of injured persons at sea and the deployment of hydroacoustic equipment. Besides the sixteen crew members, up to thirty-four additional forces can be accommodated on board. Extensive equipment is on board in order to carry out emergency towing operations successfully.

First vessel to enter service in 2023

The three new vessels will replace the multi-purpose vessels "Mellum", "Scharhörn" and "Neuwerk". The vessels which are approved for worldwide deployment will operate in German coastal waters in the North Sea and Baltic Sea.

The first of the new special vessels is scheduled to enter service in 2023, the second a year later and the third in 2025.

Source: SCHOTTEL