Energean PLC announced earlier today that it has signed an EPC contract with global process engineering business KANFA AS for the supply of a second, 700 tonne oil train for the Energean Power FPSO. The addition of a new oil/condensate separation module will increase the FPSO’s liquid production capacity from 18 kbopd to 32 kbopd.

This brownfield project will enable Energean to meet increased gas production volumes from 2023 onwards whilst allowing for optimal well and reservoir management of the Karish and Karish North fields, both of which have shown high Liquid Gas Ratios (LGR).

Furthermore, increasing the FPSO HC liquid treatment capacity by 75% will enable a more balanced distribution of offtake per well over the life of the fields, enhancing the ultimate recovery factor. KANFA AS will provide project management, engineering, procurement, fabrication, and precommissioning work for the fully assembled new module in a specialised FPSO module & conversion yard. Following completion, the topside module will be transported to the Karish field in Israel for integration onto the vessel, requiring a ship-to-ship heavy lift operation scheduled to take place in Q3 2023.

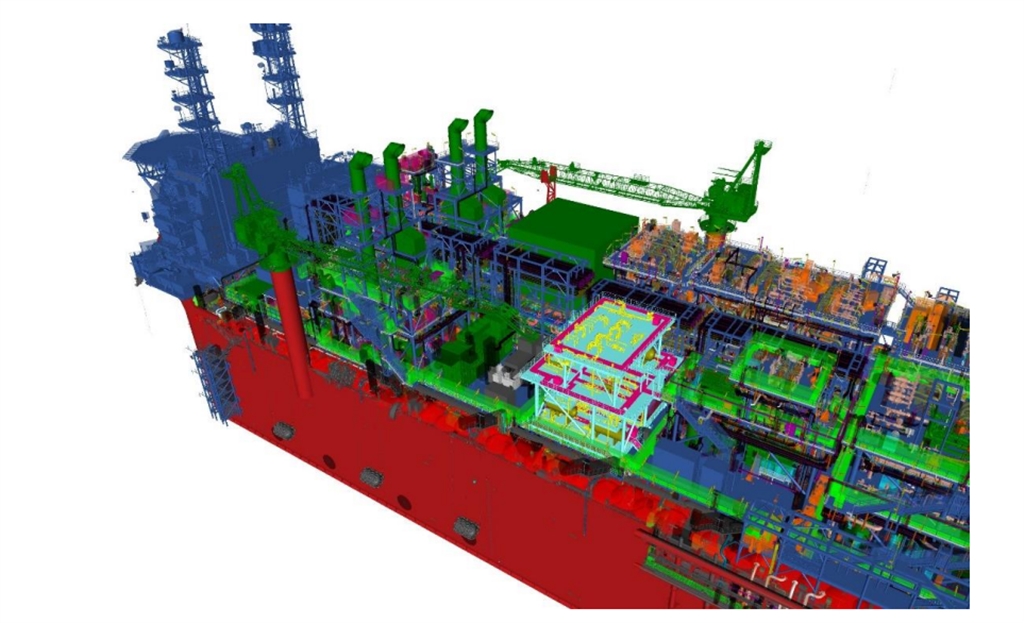

Key design considerations for the successful execution of project include the offshore heavy lift and the subsequent complex integration onboard a live facility. The new three-deck structure weighting approximately 700 tonnes will be installed aft portside on M10 pancake available deck space.

Further topside growth was anticipated and factored into the basis of the design of the Energean Power FPSO in 2017 and is now leveraged.

The new module comprises a 2nd oil separation train and a flash gas compressor package designed to operate in conjunction with existing FPSO processing systems. The 2nd oil train and flash gas compressor are identical to the original train in order to leverage O&M synergies and benefit from standardisation.

The Energean Power FPSO has been designed and built to minimise carbon emissions intensity, in line with Energean’s commitment to achieve net zero emissions ahead of 2050. The enhanced liquids production enabled by the installation of the second oil train will be achieved at no material incremental carbon emissions intensity to the overall project. Carbon intensity of Energean’s projects in Israel is expected to be 4.3 kgCO2 per boe, while sector average stands at 18 kgCO2 per boe currently. Engineering work starts immediately at KANFA’s Oslo offices supported by Energean’s Project Execution & Delivery team which was assembled a year ago.

KANFA AS was previously an EPC subcontractor to TechnipFMC between 2018-2020, specifically involved on the topside process modules of the Energean Power M1/2/3 (Inlet/Gas Trains/Oil Train) which it delivered on time during Q1 2020 in Singapore. KANFA’s previous experience on the FPSO alongside its deep knowledge of the vessel’s design mean it is uniquely placed to deliver the successful completion of this brownfield project.