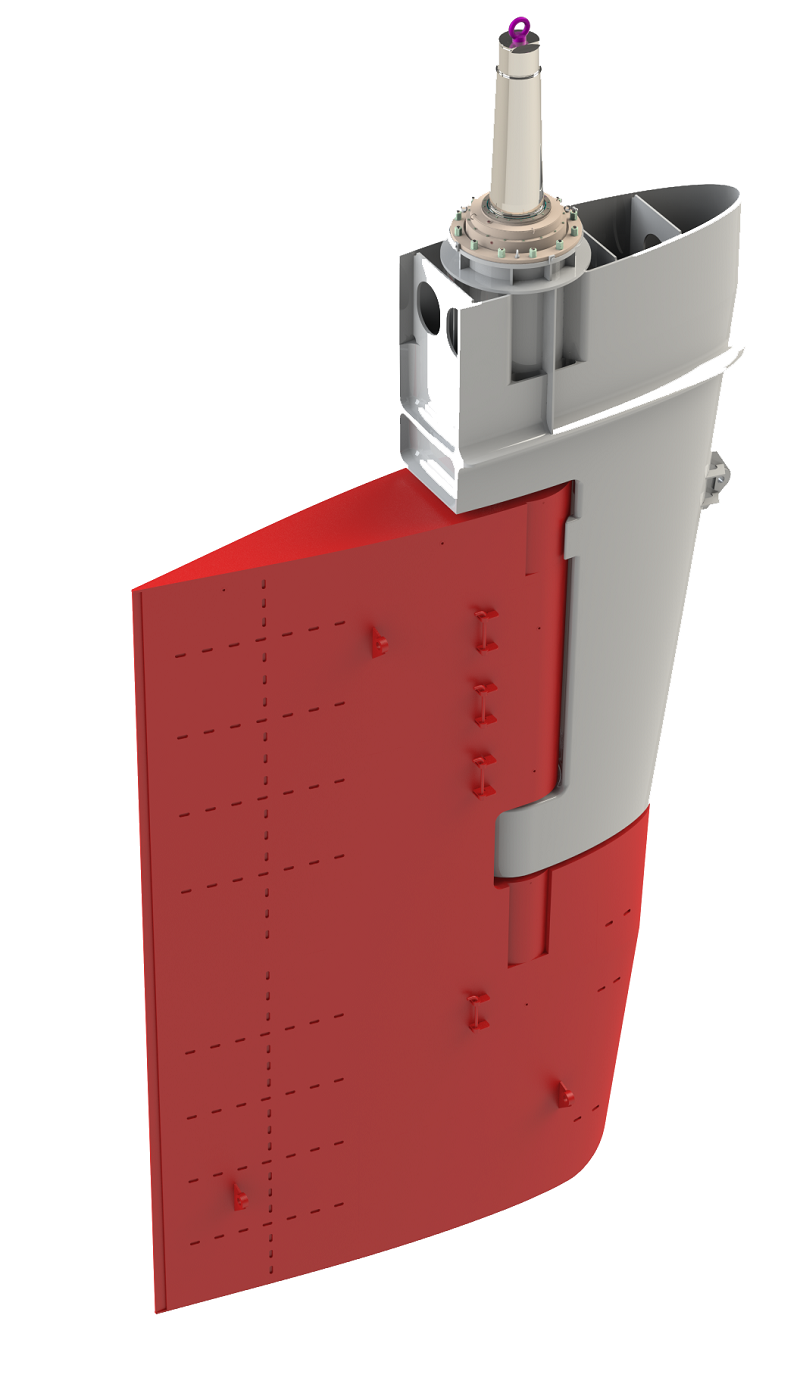

Semi spade rudders with innovative asymmetric leading edge will be installed on five new Pure Car and Truck Carrier (PCTC) vessels for Eastern Pacific Shipping from Singapore. The vessels are to be built by CSC Jinling Shipyard in China. The customised rudder will contribute in saving fuel during passages thanks to innovative design.

The five 72,000 gross ton vessels feature 12 cargo decks on which they can carry 7000 vehicles. The carriers of nearly 200 meter long, 38 meter beam and 8.6 meter design draft are laid out for a design speed of 19.5 knots. These car carriers will be propelled by dual fuel diesel-LNG engines by a single propeller. Running on LNG, these vessels will be able to sail with considerable reduction of emissions as compared to conventionally powered ships. For each of the five identical carriers, Damen Marine Components (DMC) will deliver one rudder, that will allow for even more fuel savings thanks to optimised design. The customised rudder will provide 1450 kilonewton meter of torque, the weight is 46 tonnes, excluding the horn.

Asymmetric Rudder Technology (ART) is based on advanced hydrodynamics. The asymmetric leading edge diverts the rotational effects of the propeller wake to enhance the flow along the rudder. This reduces drag and thus saves fuel. ART is often applied to the leading edge of the rudder blade, yet for the five PCTC’s also the horn of the rudder is asymmetric. This further optimisation of rudder design, enhancing fuel economy, is specially engineered for these vessels by the DMC design team.

Bogdan Mocanu, Area Sales Manager at Damen Marine Components says: “We are very glad to have the opportunity of using our expert knowledge in designing the rudders for top performance, fully complying with the ship’s operational profile.”

The five PCTC’s will be built at the China Merchant Jinling Shipyard under DNV class notation. DMC will deliver the rudders for the five consecutive carriers in the course of 2023 and 2024, in time for scheduled ship delivery from the yard.