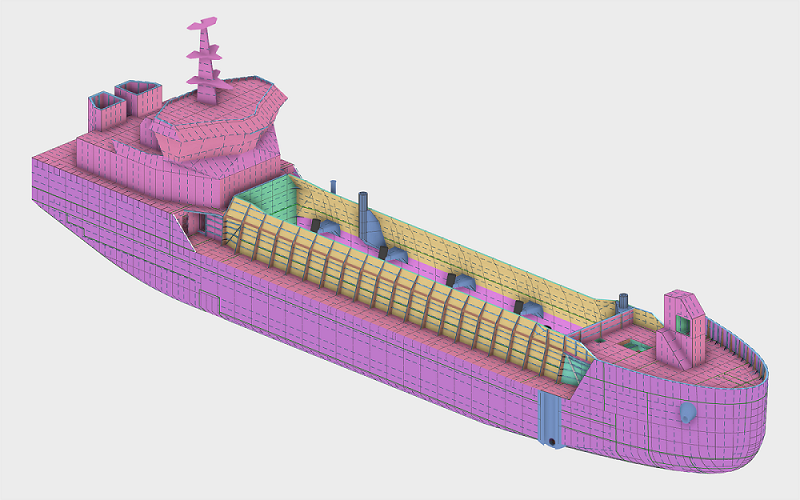

Classification society Bureau Veritas has successfully reviewed a 3D design of a 2500 m³ hopper dredger from Damen Shipyards, being a step to granting it approval in principle. The pilot project for 3D model-based class approval is meant to pave the way towards using three dimensional computer designs as standard procedure to achieve class notation for seagoing vessels.

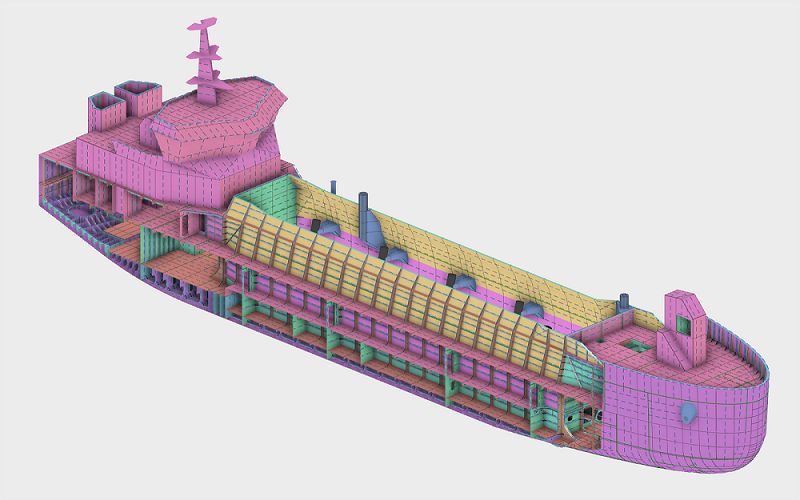

Vessel steel hull Design evaluation based on 3D models in parallel to its classification review process has become possible thanks to the new data exchange format - OCX. The OCX is an open standard that facilitates data exchange of 3D ship models for class approval.

This Open Class 3D Exchange standard has been developed by a consortium of software companies including NAPA and Aveva, together with classification societies including DNV, Bureau Veritas and Lloyds Register. In close collaboration with Finnish software developer NAPA and Bureau Veritas, Damen has presented the three dimensional design of their TSHD 2500 (Trailing Suction Hopper Dredger with 2500 m³ hopper capacity). All the mission equipment as specified for a client had been integrated into this design. Bureau Veritas assessed the steel hull structure to be strong enough and safe to SOLAS standards, with all of the heavy equipment operational.

The OCX format has been available since 2022. First pilot projects for partial designs were finished in November last year. The project for the Damen Dredger with NAPA and Bureau Veritas is the first complete steel hull to achieve class approval by 3D design. Damen intends to apply this approval process with more vessels, also in co-operation with class society DNV and others

Today’s best practice is 2D technical drawings remain an explicit requirement when naval architects and shipyards submit their hull designs to classification societies, to ensure they fulfill both Class and Statutory requirements. After the class society studies the drawings, sometimes changes are required. The designers take the remarks from the drawings and apply them in the 3D model. Then the process repeats. Presenting the 3D models to classification societies saves a lot of time and present making mistakes. Open data exchange standard facilitate exchange of 3D ship models for class approval.

“Seeing the results of this first class approval for a vessel steel hull, we are certain that this is the way to go,” Managing Director Kasia Romantowska from Damen Engineering Gdansk ensures. “Development time for the steel construction will be shorter thanks to class approval and us using 3D models only. We have more control over the technical risks embedded into a prototype vessel design process. It has been the first time that have we closed the 3D data exchange loop between parties. We expect to be able to save significant percent of design time when we integrate this way of working as a standard. The big benefit is the enhanced project team collaboration within the same, fully digital, transparent daily work context, applicable for designers and approval engineer at the same time.”

Kasia Romantowska announces more demonstrator projects for 3D model based class approval. The co-operation with Bureau Veritas and NAPA is very much appreciated, she underlines.