Propulsion efficiency solutions from technology group Wärtsilä are delivering significant efficiency gains to the shipping industry. A study of operational data has indicated significant emission reductions for two Medium Range (MR) product tankers fitted with Wärtsilä technology, and an average efficiency gain of 6% has been recorded.

The vessels, Elandra Sea and Elandra Star, owned by global energy company Vitol, and managed by Latvian operator LSC Group, had tailored Wärtsilä EnergoFlow and EnergoProFin systems installed during summer 2022.

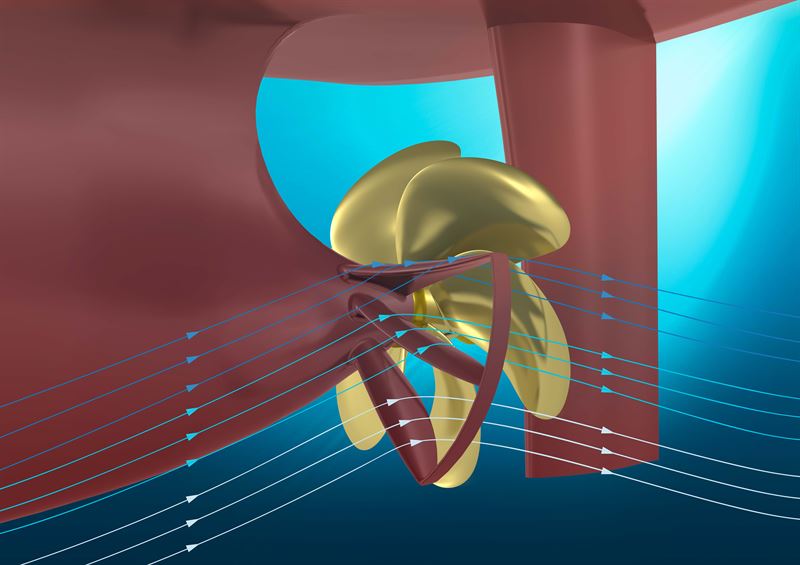

EnergoFlow is an innovative pre-swirl stator that creates an optimal inflow for the propeller, reducing fuel consumption and emissions in all operating conditions. The EnergoProFin is an energy saving propeller cap with fins that rotate together with the propeller. It reduces the energy losses created by the propeller hub vortex, increasing overall propulsion efficiency and significantly reducing underwater noise.

What’s more, the efficiencies from these two devices will help the vessels achieve their EEXI requirements and CII ratings, whilst reducing operational costs for Vitol.

“Following the successful installation of Wärtsilä products on the Elandra Sea and Elandra Star, we are pleased that two long range product tankers – the Elandra Bay and Elandra Sound – have recently left dry-dock, equipped with Wärtsilä energy efficiency products. The joint analysis of the data on the Elandra Sea and Elanda Star from last year’s installation is extremely encouraging and we will be installing future devices in 2024. This is one of a number of measures that Vitol will continue to invest in to reduce emissions and improve efficiencies across the fleet,” said Ian Butler, Head of Energy Transition – Shipping, Vitol.

“We are pleased to support Vitol in their efforts to decarbonise their fleet operations. EnergoFlow and EnergoProFin provide a benefit to cost ratio that is extremely favourable compared to alternative technologies and are clearly delivering positive results for these vessels. Furthermore, once they are installed no maintenance is required and there are no additional costs,” commented Francois Emin, Product Manager – Propulsion, Wärtsilä.

Following the success of these installations, Vitol has recently ordered an additional three EnergoFlow systems and at least four more are being considered for next year.