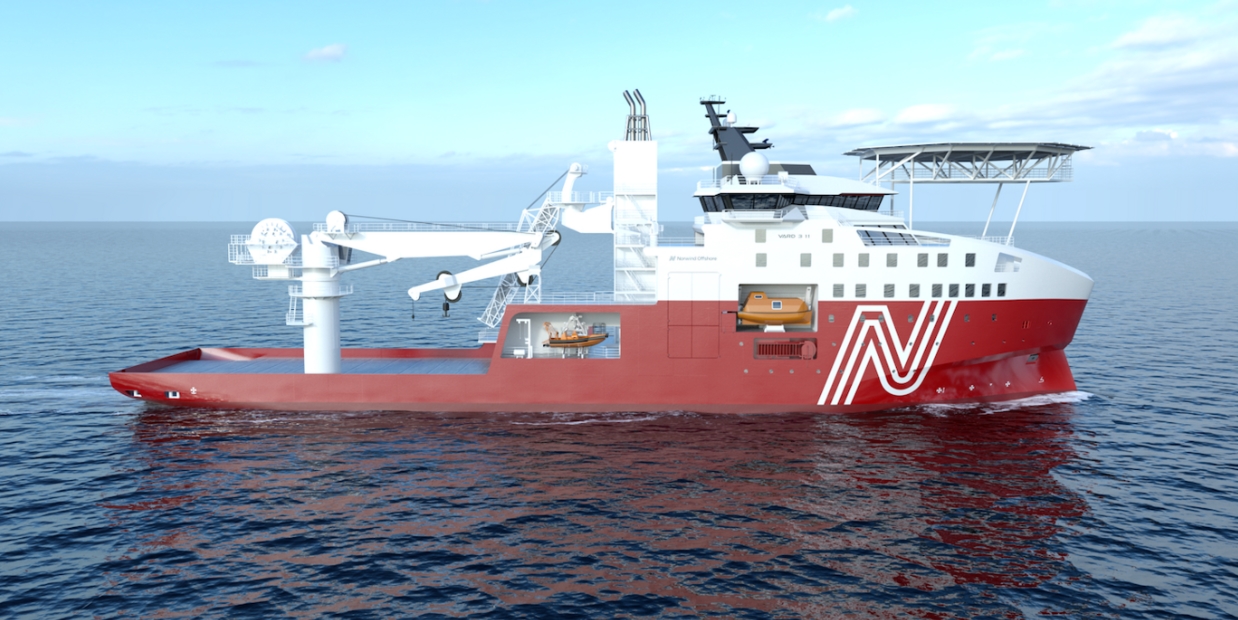

VARD has signed a contract for the design and construction of one state-of-the-art Energy Construction Vessel (ECV) with Wind Energy Construction AS. The parties have also agreed on an option for one additional vessel which can be declared later this year.

Wind Energy Construction AS is a Norwegian company partly owned by the founders and owners of Norwind Offshore AS. This is the 6th vessel the owners of Norwind Offshore have contracted with VARD since October 2021. The five previous vessels were CSOVs.

The Energy Construction Vessel (ECV) will be of VARD 3 11 design, a design tailor-made for the offshore wind and subsea market, including inspection, maintenance and repair of pipes, and construction and installation of infrastructure above and below sealevel.

The design is made for the best possible station-keeping, manoeuvrability, and sea keeping and allows for flexible configuration depending on the specific operations the vessel will perform.

This is the first construction vessel VARD will build with a motion-compensated gangway (walk-to-work) permanently installed. A walk-to-work Electric Controlled Motion Compensated (ECMC) gangway with integrated 3D compensated crane functionality will be installed. To expand capacities, especially towards the growing renewables market, a movement-compensated offshore crane of 150 tons is also being installed.

Developed a new vessel category

We are pleased to have, together with VARD, developed a new vessel category which will enable the development of renewable energy to an even greater extent.

The concept builds on vessels within the construction market which we have previously built with VARD, and we feel confident that this will play an important role in the development of, among other things, offshore wind in the coming years, says CEO in Norwind Offshore Svein Leon Aure.

VARD is a total provider on the vessel. Through our integrated value chain, we are delivering the design, building the hull, and outfit – integrate and commission the ship for the customer.

Vard Group’s high technology subsidiary Vard Electro has a comprehensive delivery of SeaQ equipment to enable sustainable solutions tailored for the vessel. This is including SeaQ Power with energy storage system of 1MWh, SeaQ shore connection for green port stays, SeaQ Bridge with full integration to all systems and an extensive SeaQ Communication package that includes network and entertainment systems.

The SeaQ Control system will have the innovative and new portable monitoring station that enhances the flexibility and accessibility for the operators to monitor and manage the maritime operations. This new tool is an integral part of the SeaQ IAS and SeaQ ePMS systems that enable digital solutions to be seamlessly shared within the cyber-proof network onboard and onshore.

Vard Interiors will deliver modern Interior solutions and green HVAC R system aiming to create a good living and working environment onboard the vessel.

VARD maintains its technological and industrial leadership

Senior Vice President Sales and Marketing in VARD, Torgeir Haugan is responsible commercial process of the contract: We are delighted that the people behind Norwind Offshore and Wind Energy Construction AS choses VARD when broadening their fleet of vessels, this time with their advanced Energy Construction Vessel targeting both the promising oil & and gas subsea market as well as strengthening the foothold in the renewable offshore wind market.

This contract shows that VARD maintains its technological and industrial leadership in the offshore market. Together with the customer we push boundaries and continue to develop our vessels to the best of our customers wanting to be a part of the green transition. We welcome Norwind Offshore and Wind Energy Construction AS back and look forward to continuous collaboration.

The vessel will be built, outfitted, commissioned and delivered from Vard Vung Tau in Vietnam and is scheduled to be delivered Q2 2027.

Technical information:

- Length of 111,5 meters and beam of 22,4 meters

- 3D Electric Controlled Motion Compensated walk-to-work gangway

- Heave compensated offshore subsea crane of 150 tons

- Accommodation for 120 POB