A new metal matrix able to float on water was presented by researchers of Deep Springs Technology (DST) and the University Polytechnic School of Engineering in New York.

For many years syntactic foams have been around but this is the first development of a lightweight metal matrix syntactic foam, which is so light.

According to researches, a boat made of such material will not sink even with damage to its structure and the systems will be more efficient due to better automotive fuel economy, which is a result of the material’s heat resistance and lightweight.

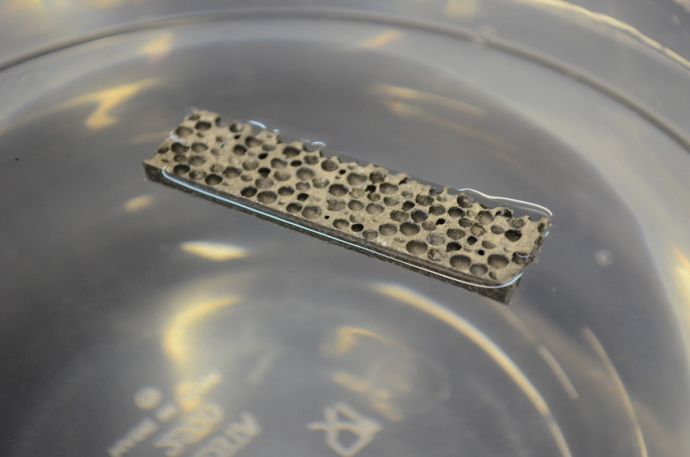

The new metal matrix composite is magnesium alloy, which is reinforced with silicon carbide hollow particles. Compared to water’s density of 1.0 grams per cubic centimeter, the new material has a density of only 0.92 g/cc.

The special feature of the material is expressed in the fact that not only it is lighter than water, but also is capable to withstand the harsh conditions of the marine environment.

In the last few years significant efforts on developing of polymer matrix composites have been made - to be light enough to replace the much more heavier metal-based components used in the automobile and shipping industry.

The new metal composite technology is expected to be used and tested on prototypes within the next three years. Because of its light weight and high buoyancy, the metal matrix syntactic foam will be especially beneficial to the U.S. Marine Corps’s amphibious vehicles, like the Ultra Heavy-lift Amphibious Connector (UHAC)

“This new development of very light metal matrix composites can swing the pendulum back in favor of metallic materials,” said Nikhil Gupta, the study’s co-author and an NYU School of Engineering professor in the Department of Mechanical and Aerospace Engineering.

“The ability of metals to withstand higher temperatures can be a huge advantage for these composites in engine and exhaust components, quite apart from structural parts,” he added.

Despite the fact that the new syntactic metal foam is light, the DST and NYU’ development has a substantial strength, which is a result of the matrix structure. The syntactic foam has a matrix originally made of a magnesium alloy, which is turned later into foam. The transformation process occurs after adding lightweight and strong silicon carbide hollow spheres developed and manufactured by DST.

The pressure resistance of a single sphere’s shell before it ruptures is more than 25,000 pounds per square inch (PSI) or equal to the maximum pressure in a fire hose multiplied hundred times.

The sphere shells act like energy absorbers during their fracture, which make the hollow particles impact protectors for the syntactic foam in case of damages.

In order to fit the application requirements, the composite can be customized for density and other properties by adding various shells into the metal matrix.

The new concept has good perspectives to be applied in boat flooring, automobile parts, vehicle armor and buoyancy modules.