Rolls-Royce has announced plans for a major programme of investment in its azimuth thruster production facility in Rauma, Finland, consolidating assembly and test capability and modernising the operation to position the business for future growth opportunities.

The €57 million (£44 million) project will include a major rebuild of existing facilities, the transfer of thruster assembly and testing onto one site from the existing two locations, and a significant investment in new equipment.

|

|

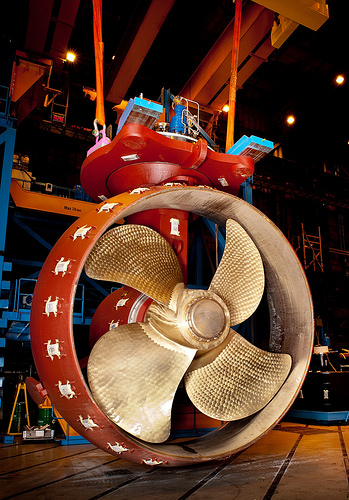

Rauma produces a wide range of mechanical azimuth thrusters for use on a wide range of applications including semi-submersible drilling rigs and drillships, tugs and offshore vessels. Rauma also produces thrusters for specialist vessels such as icebreakers and polar research ships.

Mikael Makinen, Rolls-Royce, President – Marine, said: “Our azimuth thrusters are one of our most important products, providing mission critical power and propulsion for some of the largest floating objects on the planet. To be able to make this significant investment in Rauma not only prepares us for future growth in this market, but is a vote of confidence in the capability and expertise of our people.”

Olli Rantanen, Rolls-Royce Finland, Managing Director, added: “Since the first azimuth thruster was developed here in Rauma over 50 years ago, these products have become the standard choice for customers demanding very high levels of reliability, power and performance often in extremely challenging environments. This investment will allow us to plan for the future, and enable us to efficiently produce our existing range and develop new and larger mechanical thrusters.”

Azimuthing thrusters rotate through 360 degrees, providing propulsion and manoeuvrability without the need for a rudder.

Azimuthing thrusters rotate through 360 degrees, providing propulsion and manoeuvrability without the need for a rudder.

The largest and most powerful thrusters from Rauma are the ARC type which power icebreakers including the Finnish vessel Fennica. They are among the largest products produced by Rolls-Royce and can each weigh up to 190 tonnes, providing 7.5Mw of power.

Shell’s Prelude, the world’s first floating liquefied natural gas production facility will feature three large UUC thrusters, for position keeping. The thrusters are installed in a novel arrangement that allows them to be removed and maintained within the ship.

The Pioneering Spirit, owned by Allseas, is an innovative heavy lift vessel which is used for decommissioning oil platforms – 13 UUC thrusters power this twin hulled, construction vessel.

Two of the world’s largest floating structures are powered by another range of thrusters produced in Rauma, UUC underwater mountable thrusters:

The work to transform Rauma will begin immediately and is due for completion in 2020. The investment will include installation of a crane capable of lifting 200 tonnes, and at least six factory acceptance test rigs. Offices and IT systems will also be refurbished.

Source: Rolls-Royce