In connection with the Gastech 2017 conference and exhibition in Tokyo, project partners Consolidated Marine Management (CMM), Hyundai Heavy Industries (HHI), Wärtsilä Oil & Gas, and DNV GL presented the results of a joint industry project (JIP) to develop a new LPG fuelled carrier design – LPGreen. Launched at the Posidonia trade fair in 2016, the JIP sought to develop a more energy efficient, environmentally friendly, and safer vessel for the transportation of LPG products.

“In order to increase the competitiveness of modern LPG carriers, novel ship designs need to simultaneously account for the market and trade route characteristics; excellent safety and ease of operation; cargo and fuel flexibility; and, overall energy efficiency combined with economic viability,” says Nikolaos Kakalis, DNV GL’s Manager for R&D and Advisory Services in South East Europe and Middle East.

“Therefore, a holistic approach to the design of modern LPG carriers is required, taking into advantage market insight, technology innovation, advanced computer tools and industry-wide collaboration with strong partnerships.”

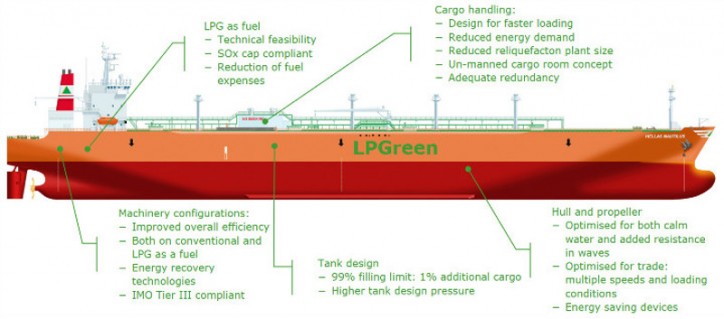

The JIP has resulted in a new concept design that achieves state of the art performance on several fronts. Compared to the reference vessel, a high specification standard design vessel built in 2016, there is an overall improvement of 6–9% in energy efficiency, depending on machinery configuration and fuel used. A redesign of the tank allows for a filling limit of 99% – a 1% increase in overall carrying capacity. Loading duration has been decreased by 30%, while the newly designed cargo handling system concept results in a 5% reduction in energy demand.

“Perhaps most importantly, LPGreen has demonstrated the technical feasibility of a LPG fuelled propulsion concept, which, depending on fuel prices and the development of a commercial and chartering framework, could result in a cut of up to 30% in fuel expenses,” says George Dimopoulos, Principal Specialist in DNV GL and project manager for LPGreen.

To realise these gains, the partners utilised advanced computer analysis tools. Hull form optimisation both in calm water and waves was conducted using HHI’s and DNV GL’s CFD hydrodynamic optimisation codes. The overall concept system evaluation and optimisation was conducted using DNV GL’s COSSMOS modelling framework, which allowed for an integrated analytical approach to the evaluation of all machinery technology options and design improvements considered. Finally, every technology feature was compared against the performance of an existing, new (2016), and very modern LPG carrier from CMM’s fleet, which gave a solid basis for documenting improvements.

”Above all, the LPGreen concept design demonstrates that the partnership and close collaboration of industry leaders coupled with advanced analysis methodologies and computer tools can lead to efficiency improvements and innovation in practice, available today”, said Nikolaos Kakalis, Manager R&D and Advisory Services, South East Europe and Middle East,DNV GL – Maritime.

Source: DNV GL