Two Ulstein designed heavy lift vessels, the 'JSD 6000' and the 'Alfa Lift' are currently in their last months of construction before entering the market in 2022 to set new standards in their respective markets.

The ZPMC shipyard, China, has reached a new milestone in the construction of the 'JSD 6000' pipelay derrick and heavy lifting vessel with the installation of the vessel’s J-lay tower in early September 2021.

The 'JSD 6000' is currently in her last months of construction before entering the market in 2022.

This customised ULSTEIN SOC5000 design has unique features as it combines a 6,000t main crane with both a centreline positioned S-lay system over the stern and an off-centre J-lay system via a moonpool.

'ALFA LIFT'

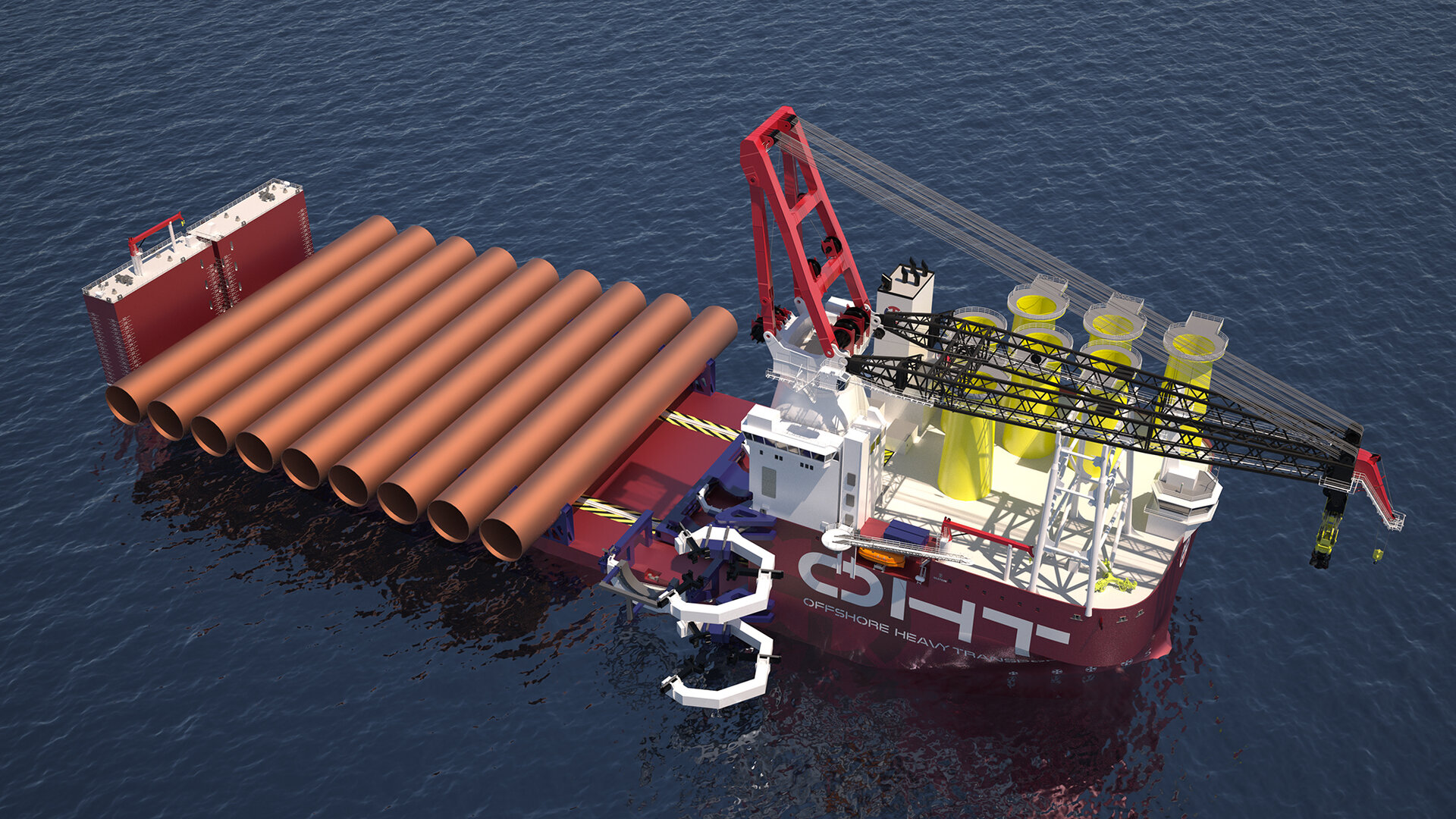

At the same time, the OHT Alfa Lift vessel is taking shape nicely. Based on the patented Ulstein Alfa Lift design, the vessel has been dedicatedly developed to serve the global offshore wind market. Because of her capabilities, OHT ASA has with this vessel been awarded the contract to install the wind turbine foundations for the world’s largest offshore windfarm Dogger Bank A & B.

Further she will be the world’s first monohull vessel able to perform heavy lift crane operations with her main deck submerged in offshore conditions. Alfa Lift featuring a vast open deck and a 3000 mt heavy lift crane, the vessel will be delivered early next year.